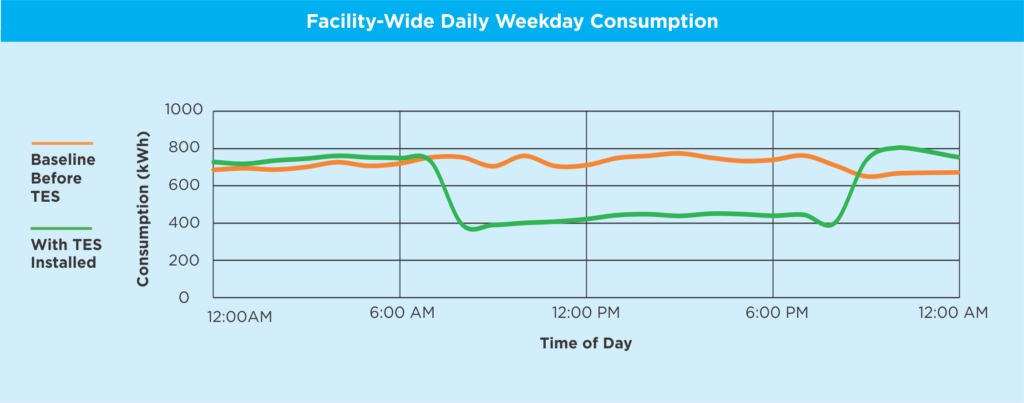

The utility rate plan for this facility includes increased pricing for kWh consumption and peak kW demand during a 13-hour peak period (8:30 am to 9:30 pm) Monday through Friday that accounts for nearly 50% of the annual energy costs at the Dreisbach facility.

___________________________________________________

TES systems are comprised of three elements: phase change material (PCM), intelligent controls, and 24/7 monitoring, reporting and notification software. When energy costs are lower and system efficiencies can be maximized, existing refrigeration equipment freezes the PCM. This allows intelligent controls to turn off refrigeration equipment for long periods of time when energy costs are high (up to 15 hours) while the PCM absorbs up to 85% of heat infiltration and maintains low energy consumption in walk-in freezers and low-temperature warehouses.

___________________________________________________

To establish the baseline performance of the freezer, all refrigeration equipment ran under normal operating conditions without Viking Cold intervention for three weeks. TES was installed, and the same data set that was recorded during the baseline was captured again and analyzed to conduct the M&V study.

Three operational variables were measured: Power Consumption (kWh), Power Load (kW), and Temperature as a function of time.

Result: Energy Consumption Reduction

Below you can see how the consumption was dramatically decreased (43%) during their peak period. Download the full study for more Consumption Reduction results, descriptions, and details.

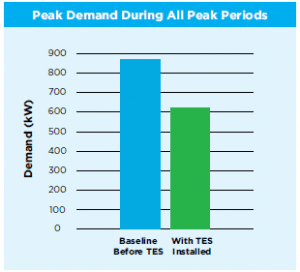

Result: Peak Demand Reduction

energy of the TES system, freezer refrigeration load could be reduced for long periods of time. The TES system lowered peak refrigeration load by 251 kW, a 29% reduction, for 13 hours each day. Download the full study for Peak Demand Reduction description and details.

Result: Greater Temperature Stability

The energy savings and cost reductions detailed above were accomplished while better maintaining operating

temperatures within the customer specified range. The data showed that with the addition of the TES system the temperature stability inside the freezer improved (50%) and was able to hold the average temperature in the room within the customer’s limit for a 15-hour duration without refrigeration.

Download the full study for hourly temperature standard deviation and more rate of rise details that describe the Improved Temperature Stability findings.

M&V Study Conclusions

The objectives of the M&V study were to determine the effectiveness of Thermal Energy Storage on energy efficiency and temperature stability with an ammonia-based refrigeration system. The results demonstrate the ability of TES to reduce energy consumption by 43% and reduce peak demand by 29% while maintaining 50% more stable temperatures in a warehouse. TES technology has significant operational and financial benefits to cold storage operators, to the cold storage industry, and to the utilities which are challenged to manage the peak loads on the electrical grid.

Download THE full case Study for a more DETAILED description of THERMAL energy storage benefits.