Thermal Energy Storage for Warehouses

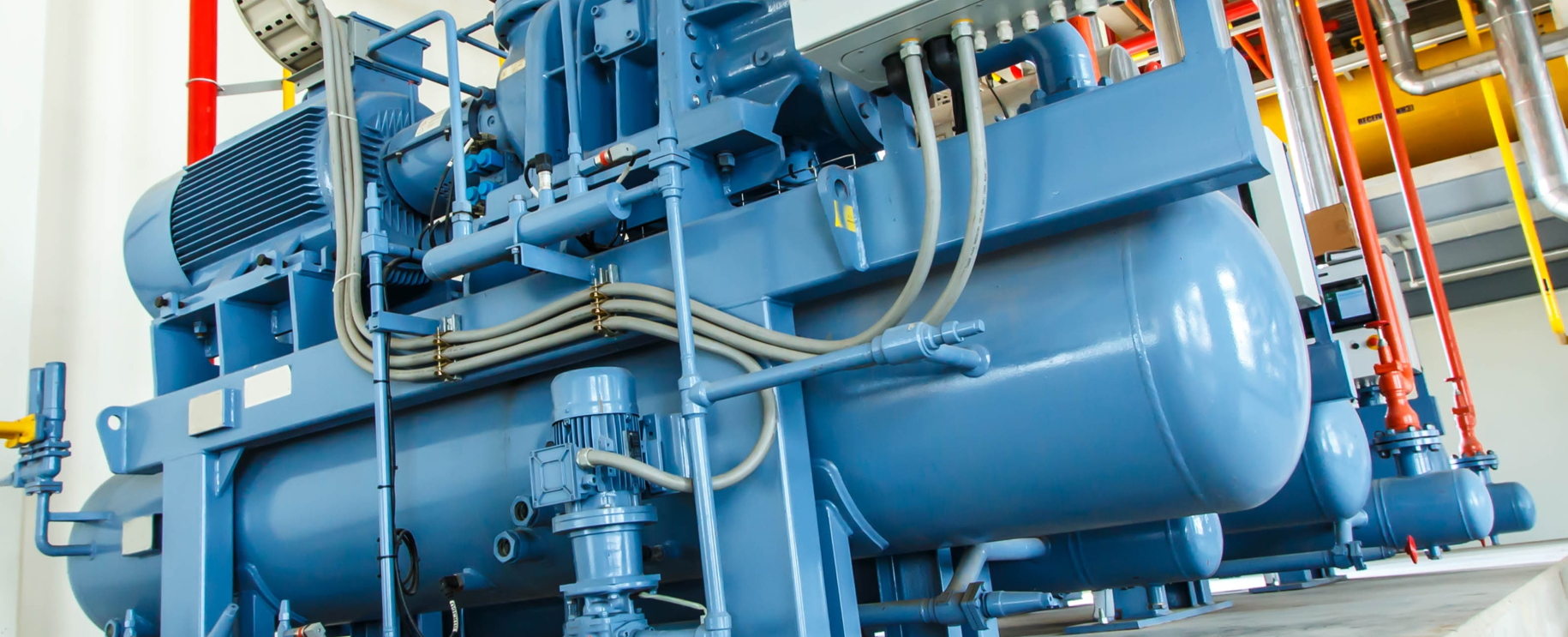

Viking Cold’s Thermal Energy Storage (TES) systems allow cold storage operators to cut energy costs up to 50%, better protect food, and improve facility resiliency. By absorbing and consolidating up to 85% of the heat infiltration, TES allows refrigeration systems to be safely cycled off for up to 13 hours each day to avoid demand or time-of-use energy fees while maintaining stable temperatures. In addition to this flexibility, TES systems increase refrigeration system efficiency an average of 26%.

Our TES systems easily integrate with existing refrigeration systems, controls, and racking structures and have been installed inside commercial and industrial frozen food warehouses and distribution centers around the world.

- Improve efficiency an average of 26%

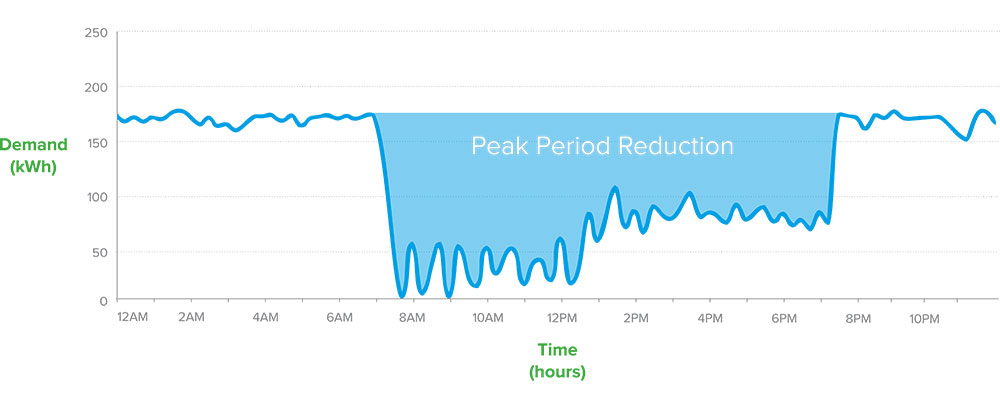

- Shift load up to 13 hours to avoid demand and time-of-use charges

- Lower pricing through demand reduction

- Increases return on renewable energy investments by pairing them with efficient long-duration storage

- Shift more run time to night

- Run compressors at maximum designed efficiency

- Absorb & consolidate up to 85% of heat in refrigeration air flow

- No moving parts that require additional energy

- PCM transfers heat 8X faster than food

- 3X longer temperture resiliency during power loss or equipment failure

- Absorbs and consolidates 50 to 85% of heat infiltration

- Reduces temperature stratification

- Reduces temperature fluctuations by half

- 24/7 remote monitoring & notification service

- Reduce refrigeration mechanical run time

- 24/7 monitoring & notification of equipment status

- Add component-level visibility with actionable data

- Reduce existing maintenance costs

- Uncover equipment issues before they become costly problems

- No additional maintenance required for TES

- More stable temperatures

- Minimize micro-thawing and large crystal formations in food

- Reporting & documentation for chain-of-cold verification

- 3X longer thermal back-up resiliency

- Reduces temperature stratification

- TES-as-a-Service fixed monthly subscription

- No upfront capital cost

- Guaranteed energy savings

- Cash-flow positive from day one

- Monitoring and maintenance included

- Off balance sheet service agreement

Watch the video to hear about the cost savings, temperature improvements, and resiliency benefits from one of our customers who has cut their annual energy costs by almost 50%.

You can also read the case study here.

The May 2019 edition of Food Logistics includes an article outlining the risks of using frozen food as a battery for flywheeling. The article also discusses using Viking Cold's Thermal Energy Storage systems as an alternative temperature capacitor to achieve even better flywheeling results, reduce the risks of flywheeling, and provide additional benefits. Utility-sponsored programs that can subsidize or entirely cover the system and installation costs are also discussed.

Those in the cold storage biz know that more thermal mass inside a freezer allows that freezer to float, or flywheel, longer without active refrigeration. But is food the right thermal mass to use to cut energy costs? Can flywheeling periods be even longer? Can more energy be saved? Can it be done without using food as the thermal battery? Read the full article published on FoodDive.com to learn how thermal energy storage improves the economic benefits of flywheeling without requiring additional energy or risking the quality of the food we put on our tables every day.

ProFood World, a leading food and beverage manufacturing publication, recognized Viking Cold's Thermal Energy Storage technology as one of the technologies empowering food producers to lower energy costs and to help reach corporate responsibility and sustainability goals.