Cold storage operators are tasked with keeping frozen food at the appropriate temperatures as it travels from farm to fork. Different foods and even different elements within the food require different temperatures to remain frozen. The key to maintaining food quality and safety is temperature stability, and Thermal Energy Storage (TES) provides more stable temperatures keeping food safe to its final destination.

Why Stable Temperatures Are Better for Food

Cold storage facilities are continuously bombarded and infiltrated by outside heat through the walls, when doors open, as people and equipment enter and move around in the freezer, and with the arrival of new product, packaging, pallets, etc. As this heat enters the facility, some is absorbed by materials (floors, racking, inventory) inside the freezer and some is immediately removed by the refrigeration equipment.

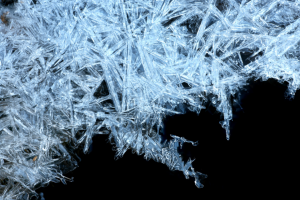

For food product, even small temperature variations can lead to micro-thawing and crystallization of various components of frozen food, which is a major factor of quality and shelf life degradation. TES absorbs up to 85% of all heat infiltration into freezers, rather than the food, and stabilizes temperatures. Thermal energy storage also reduces the rate of temperature rise by 38%. This ability to absorb heat provides an extra layer of protection for food, and also provides passive thermal backup protection for stable temperature three times longer should there be a power outage or equipment failure.

Heat rises, and temperature swings can be greater depending on the height of the facility. Because the TES is placed near the top of the racking system it keeps product throughout the facility at much more consistent temperatures, regardless of its pallet position or height. A test with and without TES inside the same freezer showed that without TES the top one-third of the facility fell outside the range of acceptable temperatures almost immediately after refrigeration was shut off. With TES, the temperature of the entire facility stayed within the acceptable range without refrigeration for over 15 hours.

How TES Saves Money

TES isn’t just better for protecting the food inside cold storage faculties, it saves up to 35% of energy costs associated with refrigeration. These costs come from two key abilities of TES.

First is the flexibility TES provides to buy, store, and use energy when it’s most cost-effective (outside of peak period energy pricing periods). During off-peak hours, the facility’s existing refrigeration equipment freezes the non-toxic, environmentally-safe phase change material (PCM). During peak hours, operators can dramatically reduce mechanical run time (up to 90%) of the costly, grid-dependent refrigeration systems while the PCM absorbs and stores 85% of all heat infiltration in the freezer, maintains temperature stability to ensure food quality and shelf life, and helps avoid expensive demand-based energy pricing.

Second is the efficiency TES provides the refrigeration system. When TES is integrated, refrigeration equipment typically runs at night with lower ambient temperatures. Additionally, the equipment is run “fully loaded”, which means it runs at its engineered maximum efficiency, rather than running constantly at a much lower efficiency. Lastly, the heat TES absorbs is stored inside PCM that allows heat to be transferred much easier than frozen food. All of this means that more heat is removed using less energy.

TES is protecting frozen food quality and is changing the face of the cold storage industry. Soon thermal energy storage will be standard in all warehouse, grocery, and restaurant freezers around the globe.

Learn more about how Viking Cold’s TES technology works and how it can help your cold storage or grocery business.