New Jersey Funds Thermal Energy Storage Systems to Cuts Energy Costs

New Jersey’s Clean Energy Program is funding Thermal Energy Storage (TES) technology from Viking Cold Solutions that improves sustainability and resiliency while cutting energy costs.

This is helpful to food producers, food distributors, and retailers because this year PSEG (as well as other NJ-based IOU’s) announced rate increases as approved by the Federal Energy Regulatory Commission (FERC) for Network Integration Transmission Service rates commonly referred to as NITS. These charges allow utilities to recover cost of operations through the grid operator like PJM.

Competitive or third-party electricity suppliers are obligated to bill and collect NITS charges as part of their supply agreements. In 2020, NITS charges are increasing by as much as 30% compared to last year for PSEG customers. Because suppliers have no ability to controls these costs, many are forced to pass these costs through to you even on “fixed price” arrangements.

This means all commercial and industrial PSEG customers will see price increases immediately or in their next procurement cycle.

Cost Benefits of TES for NJ Cold Storage Facilities

Despite these rate increases, there is good news for cold storage operators in New Jersey. Thermal Energy Storage (TES) from Viking Cold Solutions reduces energy consumption and costs now, to help offset this year’s increases, and provides flexibility to lower energy costs into the future, as rates continue to rise.

1. TES cuts costs immediately by reducing overall energy consumption (kWh) and providing the flexibility to avoid coincident Network Service Peak Load or NSPL values by lowering usage during these periods. See how it works in the video above.

2. When it comes time for energy contract renewal, TES gives you leverage to negotiate better supply rates by putting you in control with a highly flexible asset like TES.

3. TES qualifies for custom incentive programs for energy reduction through New Jersey’s Clean Energy Program.

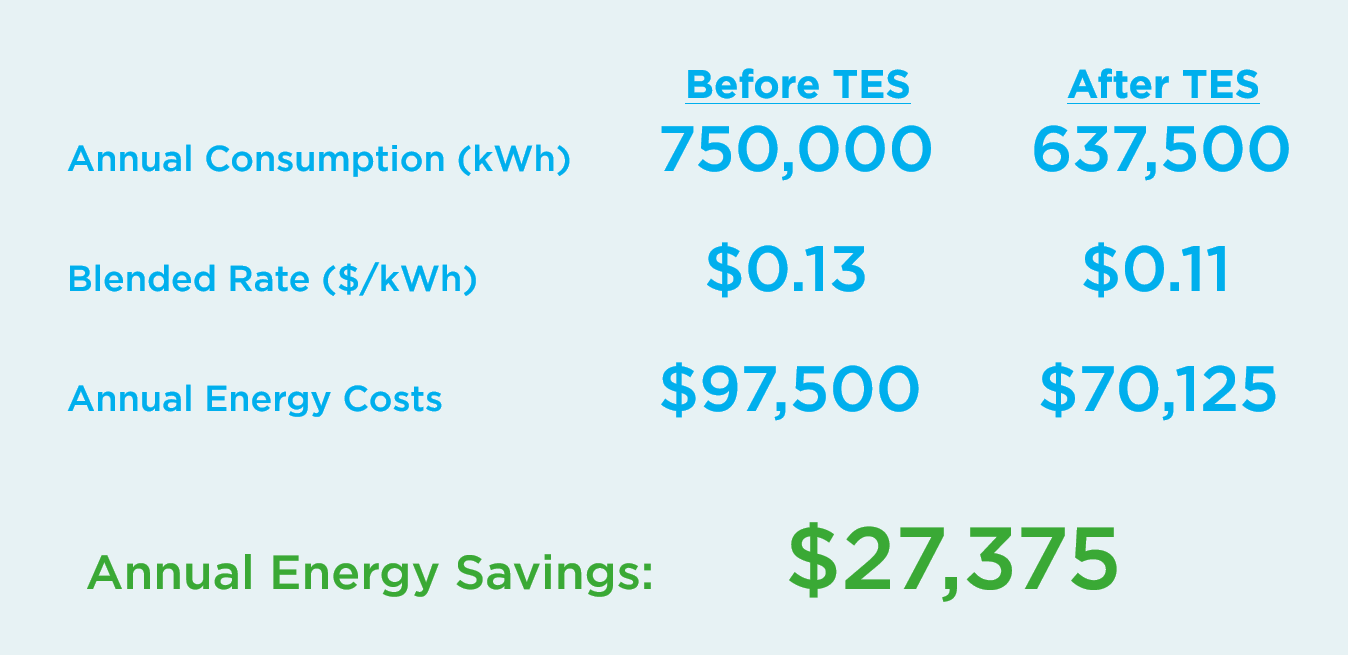

TES Rate Increase Example

FoodX Inc. operates a 50,000 sqft refrigerated warehouse using 750,000 kWh of electricity per year. They purchase their power from ACME Energy for $0.10/kWh where capacity and transmission (cap and trans) costs make up approximately 3 cents of this cost. FoodX pays $0.13/kWh combined for supply and delivery charges. With TES FoodX can negotiate cap and trans costs down by 2 cents and reduce usage by 15% (maybe more) to lower their energy spend over $27,000 per year.

Visit our TES for Cold Storage Warehouses page to learn more about the energy, temperature, resiliency, and sustainability benefits of our cutting-edge thermal energy storage systems.

Watch the video to hear about the cost savings, temperature improvements, and resiliency benefits from one of our customers who has cut their annual energy costs by almost 50%.

You can also read the case study here.

More videos, case studies, white papers and other resources here.

Food Processing – Emerging Food Safety Technologies

Food Processing – Emerging Food Safety Technologies

Food Processing Magazine has published an eHandbook outlining new technologies that food processors can use to improve food safety and food quality in their operations. A number of new food processing technologies and their benefits are described including the food quality and energy-saving benefits of thermal energy storage.

Food Logistics – Should Frozen Food Be a Battery?

Food Logistics – Should Frozen Food Be a Battery?

The May 2019 edition of Food Logistics includes an article outlining the risks of using frozen food as a battery for flywheeling. The article also discusses using Viking Cold's Thermal Energy Storage systems as an alternative temperature capacitor to achieve even better flywheeling results, reduce the risks of flywheeling, and provide additional benefits. Utility-sponsored programs that can subsidize or entirely cover the system and installation costs are also discussed.

ProFood World - Transform your operation from energy consumer to energy producer

ProFood World - Transform your operation from energy consumer to energy producer

ProFood World, a leading food and beverage manufacturing publication, recognized Viking Cold's Thermal Energy Storage technology as one of the technologies empowering food producers to lower energy costs and to help reach corporate responsibility and sustainability goals.