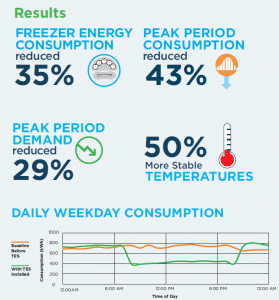

Proven Peak Period Results: 43% Less Consumption, 29% Lower Demand

The objectives of the M&V study were to determine the effectiveness of TES on demand management, energy efficiency, and temperature stability with an ammonia-based refrigeration system.

The M&V study concluded that TES provided a 43% decrease in peak period consumption and a 29% decrease in peak demand while improving overall temperature stability by 50% in a frozen food warehouse.

Post-study load analysis reports from the utility continue to show 300-500 kW shed for 13 hours, 6 days each week.

Grid Benefits of TES

Why should utilities focus on cold storage? Because it has the #1 highest demand per cubic foot and the #3 highest consumption of any industrial category on the grid. And now there is a behind-the-meter, long-duration energy storage technology with an LCOE < 2¢/kWh that can handle the high demand and continuous refrigeration run time these facilities require.

Viking Cold’s Thermal Energy Storage (TES) technology with intelligent controls allows the energy-intensive refrigeration equipment to be cycled off for up to 13 hours per day in numerous demand management strategies across the grid.

Our TES technology has been tested, accepted, and incentivized by many utilities across North America, and our systems are installed and running in warehouses, grocery stores, and restaurants in multiple countries.

Download the case study for more detailed results of thermal energy storage that benefit the grid.

CUSTOMER VIDEO: HEAR THE RESULTS DIRECTLY FROM THE FACILITY OWNER.

Utility Benefits of Thermal Energy Storage

Levelized Cost of Energy (LCOE) < 2 cents per kWh

Long-duration, behind-the-meter storage + efficiency

Stores up to 500+ kW, discharges up to 13 hrs/day/facility

Quick, easy install: 1000s of existing C&I refrigerated facilities

Addresses variability of renewables

24/7 Remote monitoring & notification

Utility tested, accepted, and incentivized technology

Download the Utility and Grid Benefits brochure to quickly see how Viking Cold’s long-duration Thermal Energy Storage technology is addressing shifting demand patterns, variability of reneables, and the need for more distirbuted energy resources.