Food Logistics honored Viking Cold’s Thermal Energy Storage (TES) technology with the Top 3PL & Cold Storage Provider award for 2024! This award recognizes industry leading third-party logistics and cold storage providers in the cold food and beverage industry. Our TES technology was highlighted for making the world’s refrigeration and cold storage systems more efficient, flexible, resilient, and sustainable.

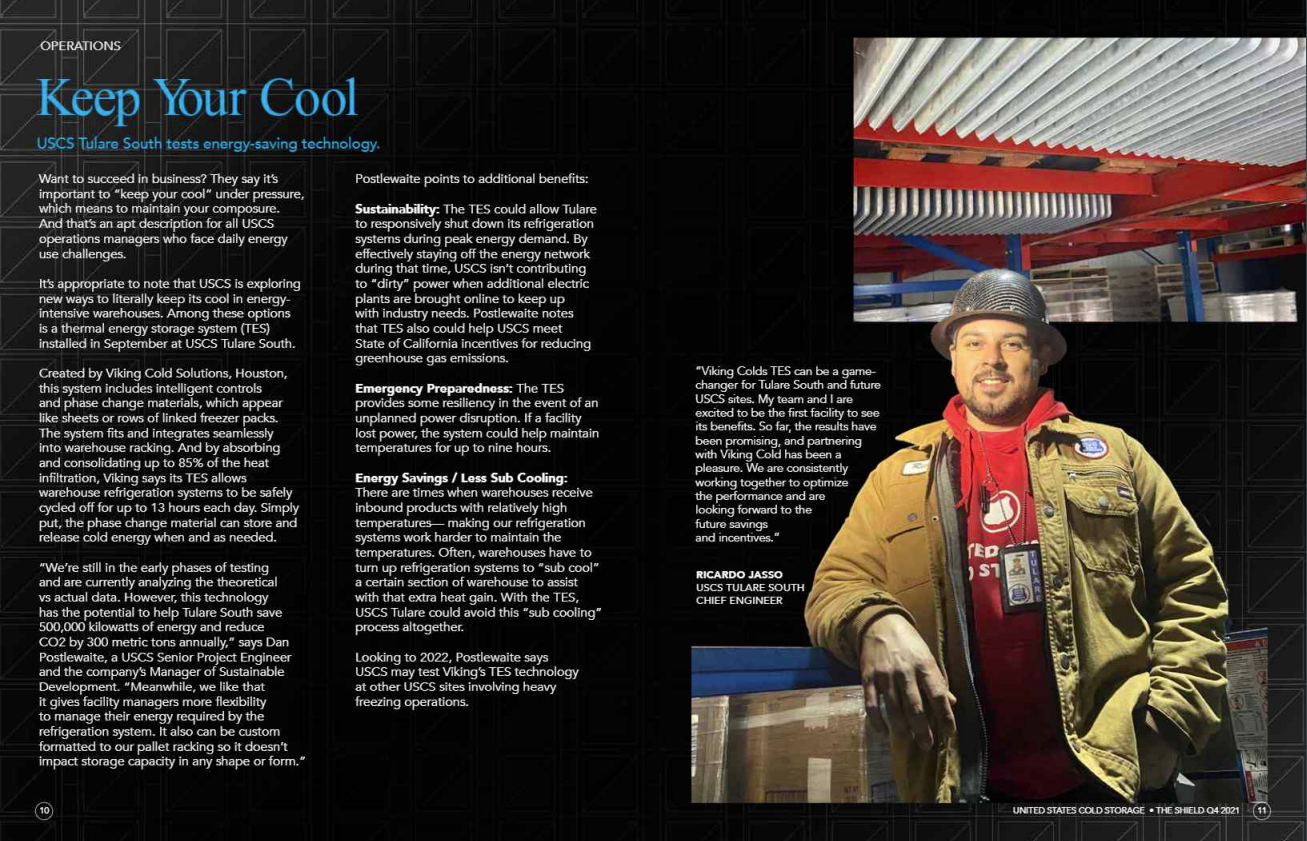

With TES technology, cold storage operators can increase refrigeration system efficiency by 20-30% and cut energy costs up to 50% while better protecting products. Maintaining consistent temperature control, despite mechanical issues, grid interruptions or natural disasters, is critical for preserving product quality and safety. Our TES systems integrate easily and have been installed in commercial and industrial frozen food warehouses and distribution centers around the world.

“3PLs and cold storage providers remain a key puzzle piece to building and nurturing partnerships, cultivating resilience and helping companies in the cold food space overcome supply chain disruptions,” says Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive. “Seventy-six percent of the winners plan to invest in software solutions this year. This is indicative of how forward-thinking these 3PLs and cold storage providers are, and how despite disruptions and other challenges, they continue to forge ahead.”

Food manufacturers, 3PLs, supermarkets, and restaurants adoption of Thermal Energy Storage technology is helping the broader food industry decarbonize today. By leveraging TES, these businesses reduce energy usage, lower their carbon footprint, and more efficiently store renewable energy.

Viking Cold Solutions provides innovative technology to support a more sustainable and resilient cold chain. To see how we can help optimize your facility, check out cold storage benefits of TES. For more information on Thermal Energy Storage contact sales@vikingcold.com.