Energy storage is a rapidly evolving technology and has been advancing to the forefront of the electrical industry, shifting the focus to the effective integration of renewable energy. Various international enterprises recognized the increasing value of energy storage and have created World Energy Storage Day to commemorate its significance. This global movement is celebrated on September 22nd every year by policy officials, associations, and industries working to promote and adopt energy storage, e-mobility, and green technology for a more sustainable future.

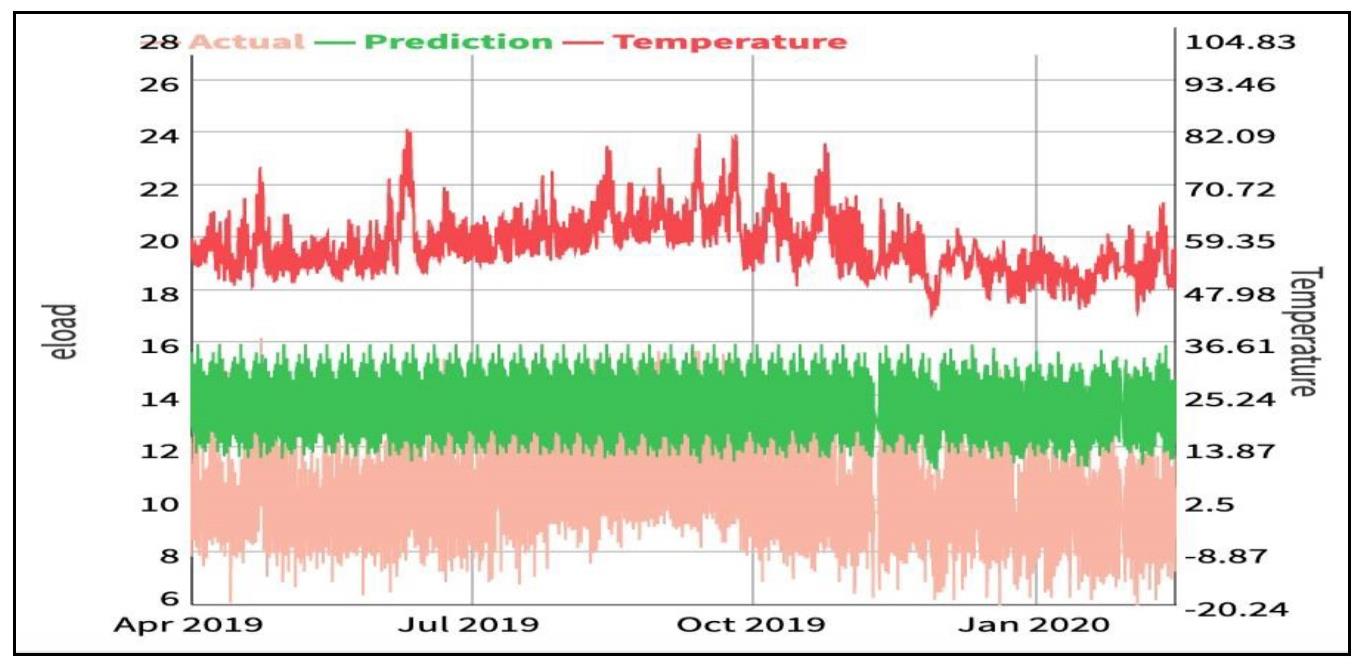

According to the Energy Storage Association, energy storage is an enabling technology; it saves consumers money, improves reliability and resilience, integrates generation sources, and helps reduce environmental impacts. It’s a key element for the entire grid, augmenting resources from wind, solar, and hydropower as well as nuclear and fossil fuels, demand-side resources, and system efficiency assets. By tapping into energy storage during outages, businesses can continue normal operations and avoid costly disruptions. When demand shifts and baseload resources can’t react quickly enough, energy storage can inject or extract energy to match the load as needed, making the grid more responsive and reducing the need to build backup power plants.

The effectiveness of energy storage is based on its ability to respond quickly to changes in demand, the rate at which energy is lost during the storage process, the total amount of energy it can store, and the speed at which it can be recharged. More than 90% of global grid battery storage is dominated by lithium-ion batteries, which are today’s most widely used battery storage alternative, reports the Environmental and Energy Study Institute. However, there are multiple types of energy storage that can provide large-storage capacities, such as pumped hydro, compressed air, and thermal.

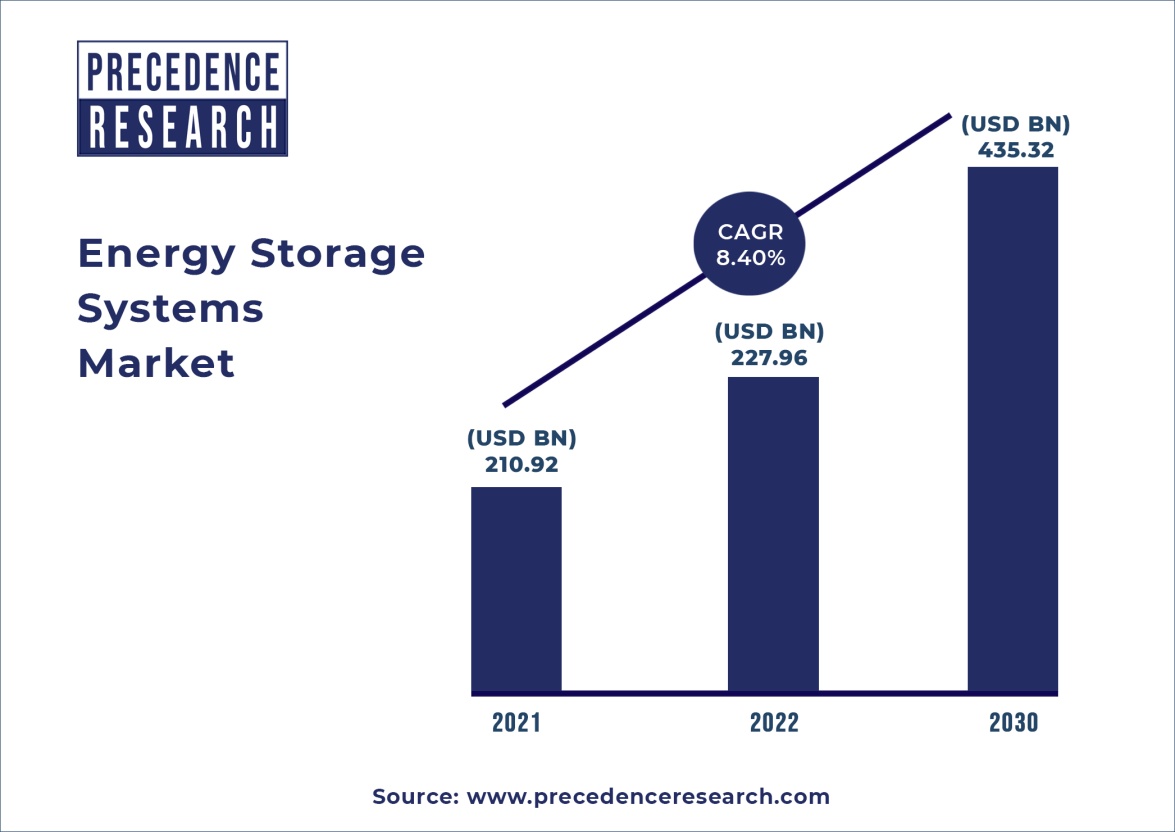

With the rapid development of energy storage, business owners and policymakers are looking towards more environmentally friendly sources of energy storage beyond lithium-ion batteries. According to Precedence Research, the global energy storage systems market size is projected to surpass $435 billion by 2030 and grow at a CAGR of over 8% from 2022 to 2030.

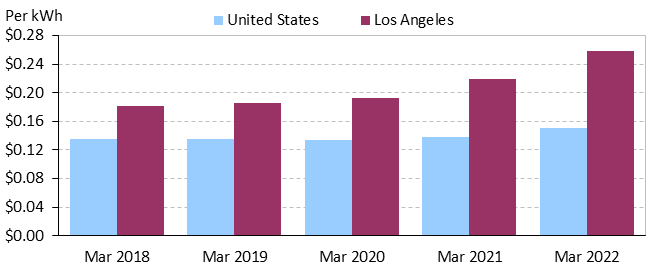

Record investments in energy storage are being fueled by declining costs and new incentives. As reported by the Environmental Defense Fund, costs for energy storage have declined by 74% since 2013 and are projected to decline 8% per year through the mid 2020s.

In fact, the cost of some storage has decreased so quickly that many utilities are switching to renewable energy combined with storage instead of investing in expensive new natural gas power plants. Over the next ten years, combining energy storage with renewable energy sources could completely change the way we purchase, sell, and utilize energy. State and Federal laws, such as the Inflation Reduction Act of 2022, are also opening new market opportunities and revenue streams, which will be the primary driver of growth outside of cost. Incentives can bridge market gaps and assist in further market adoption.

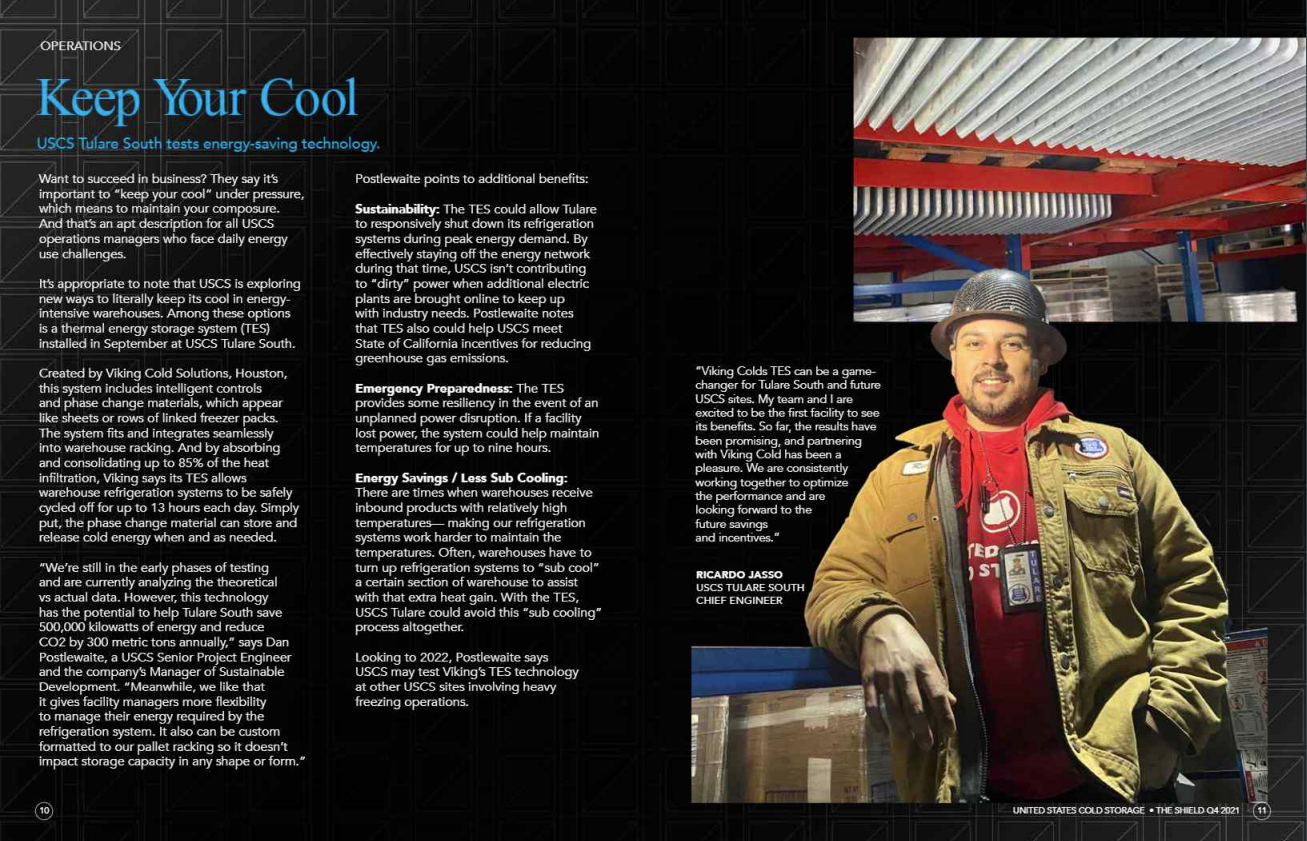

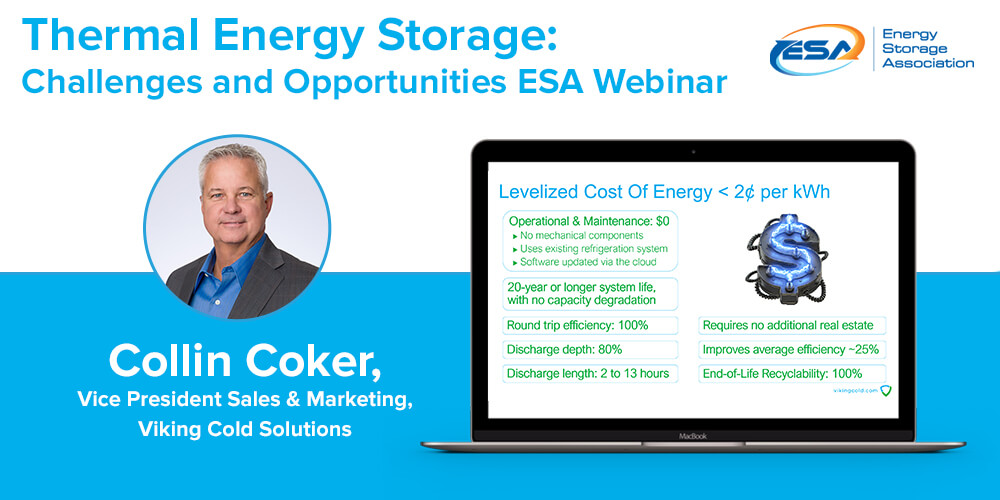

In the U.S., certain industries such as cold storage, consume over $50 billion in energy annually. Refrigeration energy cost is one of the top operating expenses which drives demand from operators for energy reduction technologies. These businesses include over 4,200 cold storage warehouses, more than 40,000 grocery store freezers, and over 620,000 restaurant freezers. To help these businesses, Viking Cold Solutions developed and commercialized thermal energy storage technologies that offer both sustainability benefits and deliver proven 20% to 35% energy savings in temperature-controlled environments.

With the growing concern over the prices of fossil fuels, their environmental impacts, and the capacity and resilience of energy grids around the world, stakeholders are increasingly turning their attention to energy storage solutions. To learn about how thermal energy storage technology reduces energy use and carbon emissions while increasing resiliency, click here.