Refrigeration Engineers Presentation – Efficient, Flexible, Sustainable Refrigeration with Thermal Energy Storage

Brad begins his presentation with relevant cold chain statistics about facilities where refrigeration optimization with intelligent Thermal Energy Storage is being achieved by leveraging PCM. He also explains some of the unique thermodynamic properties of PCM that allow TES systems to achieve positive refrigeration energy and temperature management results. He then covers how the PCM is configured and easily installed into various cold storage refrigerated facilities without additional space requirements or the loss of valuable storage area.

Also covered in the presentation is a brief evolutionary history of the refrigeration practice known as flywheeling – subcooling the food and surrounding room to then minimize refrigeration during periods with high energy costs. Brad discusses factors that influenced the start of flywheeling, are transforming flywheeling practices with new technologies, as well as how PCM safely extends the length of flywheeling periods while reducing the risk to food quality and shelf life. He also shares how PCM is able to slow temperature increases in a room without active refrigeration and shows case study data illustrating a reduced rate-of-rise and improved temperature stability.

Inside cold storage facilities temperature stratification throughout the room generally occurs. Brad shows some examples of how properly installed PCM combined with intelligence reduces the extent of temperature stratification and creates a more uniform temperature across the vertical space of these refrigerated rooms. With the introduction of PCM a new “stratification floor” is created that consolidates more of the heat near the ceiling in the airflow of the evaporators for improved temperatures around the food and for easy removal of the heat by the refrigeration system.

Thermal Energy Storage is often considered a way to simply shift when energy is consumed by refrigeration systems. Brad explains many of the factors that allow Viking Cold’s TES technology to not only shift the timing of refrigeration but also to safely reduce the total kWh energy consumption (energy efficiency) of the refrigeration systems. Hear about the factors that enable this such as reducing the horsepower per ton ratio, the ability to run refrigeration systems at maximum designed efficiency or “fully loaded”, the consolidation of up to 85% of the heat infiltration near the top of the room, the PCM’s higher heat capacity and heat transfer rates, and the fact that TES systems do not have mechanical components that cannibalize the energy savings with parasitic losses.

Also discussed in this refrigeration engineer’s presentation are additional attributes of TES that provide energy flexibility and the ability to safely and easily participate in multiple utility and grid operator programs. Many of these programs reduce costs, some provide financial incentives for technology upgrades, and some programs can generate revenue streams for operators of refrigerated facilities. The added refrigeration flexibility from TES enables participation in programs such as demand response, permanent load shed, targeted load shed, peak shaving, responding to market index pricing signals, renewables plus storage, and capacity programs.

Temperature resiliency inside the refrigerated cold chain is paramount to maintaining food quality and shelf life while minimizing food loss. Brad also explains how PCM adds resiliency to cold storage rooms. Common scenarios that disrupt cold storage operations and create a need for temperature resiliency are becoming more common and include mechanical breakdown of refrigeration system components and loss of power from ice storms, hurricanes, wildfires, utility-initiated de-energization, and more. Refrigerated facilities that have TES installed have up to three times longer temperature protection during any of these situations that may cause the loss of refrigeration.

Whether you are a facilities or business leader, refrigeration engineer, cold storage operator, or somewhere in the temperature-controlled cold chain, there is something in this short professional association presentation for you. Quickly learn about mitigating risk, cutting costs, improving sustainability, stabilizing temperatures, and more.

Click above to watch this short 21-minute refrigeration engineer professional association presentation. Or contact us today to learn how our refrigeration optimization and thermal energy storage solutions will save you energy and money.

New Warehouse Podcast: Digitization & Sustainability in Refrigerated Warehouses

The conversation also covers some of the additional levels of complexity of refrigerated spaces and how the impacts of the pandemic have driven the adoption of technologies such as WMS, automation, robotics, and thermal energy storage inside refrigerated warehouses. James and Kevin also discuss the market conditions driving more construction of cold storage facilities and how digitization and new technology is being included in the design and building of new warehouses.

Additionally, Kevin and James cover the electrical grid impacts of refrigerated spaces, and how with thermal energy storage and warehouse digitization operators can reduce costs and create new revenue streams.

Listen to the full conversation on the podcast here: EP 150: Digitization and Sustainability in Refrigerated Warehouses with Viking Cold Solutions

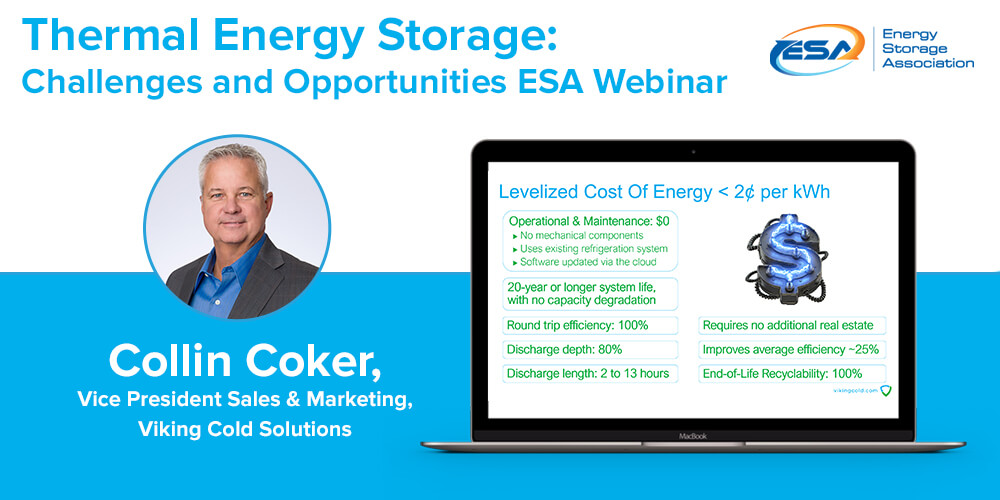

Viking Cold Adds Voice to ESA Webinar

Viking Cold provided insight into the advantages of its Thermal Energy Storage technology as part of an educational webinar hosted by the Energy Storage Association (ESA).

The session, titled Thermal Energy Storage: Challenges and Opportunities, gave ESA members a chance to learn about the technologies and trends shaping the thermal energy storage sector, forming part of the association’s work to help establish a more resilient, efficient, sustainable, and affordable electrical grid.

Marc Chupka, ESA’s Vice President of Research and Programs, welcomed Collin Coker, Vice President Sales & Marketing, to share an overview of Viking Cold’s Thermal Energy Storage technology and highlight how it fits into this landscape.

Coker explained how TES has a drastically lower levelized cost of energy (LCOE) of two cents per kilowatt-hour (kWh), making it far more cost-effective than conventional electrical storage mediums, such as lithium-ion batteries.

He briefed the ESA audience on the phase change materials (PCM) at the heart of Viking Cold technology, describing how it demonstrates significantly higher heat-absorption rates compared with frozen food, while continuously releasing cold energy to provide stable temperatures that protect products held in commercial & industrial (C&I) warehouse environments as well as grocery store and restaurant walk-in freezers.

Coker pointed to the fact that resiliency is built into the Viking Cold TES solution since no power is required and the PCM can hold temperatures three times longer than the thermal mass of food alone, helping defend chilled environments against power outages, natural disasters, and mechanical failures.

With intelligent controls to manage energy release over extended periods and 24/7 visibility of energy, temperature, and operational data, Coker added that Viking Cold brings greater levels of efficiency to cold chain environments while enhancing sustainability efforts. In the case of one customer, net power consumption has declined by 43% over a 13-hour period along with a 29% peak demand reduction, he said.

Coker went on to highlight successful utility-supported programs involving Viking Cold’s TES technology, which includes a multi-customer project involving some of the largest food distribution companies in the world. In total, this initiative accomplished 1.3 megawatts (MW) of energy curtailment over a four hour ICAP period.

He concluded with the findings from a third-party measurement and verification study, showing how one site is using Viking Cold’s TES technology in combination with excess solar power generation during the day to achieve a 95% reduction in overnight energy consumption, effectively taking the site off the grid.

The ESA webinar is available in full, including access to the accompanying slides, via the ESA’s YouTube channel.

For more information on how Viking Cold’s Thermal Energy Storage is bringing greater levels of resiliency, efficiency, sustainability, and affordability to cold chain environments, get in touch with us today.

Webinar: PLMA Thermal Energy Storage as a Grid Asset

Podcast: Risk Reduction to the Cold Chain – MarketScale Energy

Read More →

Podcast: Smart Grid Today Discussed Long-Duration Energy Storage

Read More →

GCCA: Cold Chain Innovations Webinar Series

View the webinar playback here.