Release: Study Confirms 43% Decrease in Energy Consumption in an Ammonia-Refrigerated Warehouse with Viking Cold’s TES Technology

Richmond, CA and Houston, TX (Business Wire) — Viking Cold Solutions, the leading Thermal Energy Storage (TES) provider for the low-temperature cold storage industry, announced that its measurement and verification (M&V) study on Viking Cold’s TES technology at Dreisbach Enterprises’ 93,000 square foot frozen food distribution center in Richmond, CA shows significant operational and financial benefits for utilities and the cold storage industry. The study demonstrated the ability of TES to mitigate the facility’s 13-hour peak period by simultaneously:

- reducing peak period energy consumption by up to 43 percent

- reducing peak demand within this peak period by up to 29 percent

- maintaining 50 percent more stable temperatures

Read More →

Frozen Foods Europe Exclusive: Protecting Food Supply in Extreme Weather

Weathering the Storm: Frozen Food Protection from Power Failures (Progressive Grocer Guest Blog)

How Grocers Can Lead the Charge to Reduce Food Waste & Save On Energy (Progressive Grocer Guest Blog)

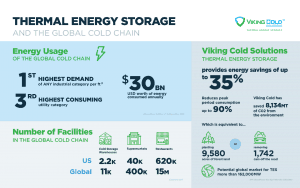

Energy CIO Insights Features Viking Cold’s Thermal Energy Storage

Online and print publication Energy CIO Insights features Viking Cold’s technology and the energy flexibility it provides through an interview with our

CEO, James Bell.

James describes how our Thermal Energy Storage (TES) technology protects food, saves energy in the global cold chain, and benefits utilities.

Access to Refrigeration Load on UtilityDive.com

Utility Dive provides professionals with a bird’s-eye-view of the utility industry through industry news, original analysis, and published in-depth feature articles.

Thermal Energy Storage: The Key to Energy Efficiency in the Cold Chain (Progressive Grocer Guest Blog)

Progressive Grocer has been the voice of the retail food industry since 1922. By anticipating, reporting and interpreting the grocery industry’s top trends and information, Progressive Grocer fulfills its mission to stay Ahead of What’s Next.

Green Lights for Thermal Energy Storage (Feature Article in Frozen Foods Europe)

Frozen Food Europe is dedicated to management level professionals in the frozen food industry: retailers, food service and catering, importers, exporters, producers, equipment manufacturers, providers of cold storage solutions, and processing plants and factories.

Release: Viking Cold Installs Another Thermal Energy Storage System in California at Dreisbach Enterprises’ Warehouse

RICHMOND, Calif. & Houston–(BUSINESS WIRE)–Viking Cold Solutions, the leading Thermal Energy Storage (TES) provider for the low-temperature cold storage industry, today announced it

Low-temperature cold storage facilities require the highest energy demand per cubic foot of any industrial electricity load. In some markets, peak demand charges comprise up to 70 percent of a facility’s electricity bill, encouraging customers to shut off equipment during peak periods. This ‘fly-wheeling’ tactic can cause micro-thawing and micro-freezing, which degrades cell structure and reduces the quality and shelf life of foods. TES serves as a much-needed heat sink to manage heat infiltration, protect product, increase refrigeration efficiencies and reduce peak demand costs.

Read More →