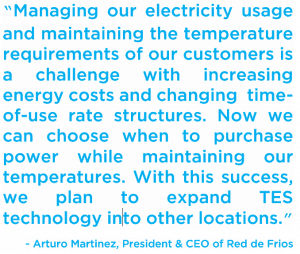

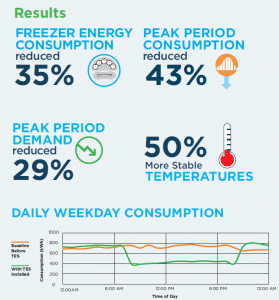

MONTERREY, MEXICO and HOUSTON, TX (Business Wire) – Viking Cold Solutions, the leading Thermal Energy Storage (TES) provider for the low-temperature cold storage industry, announced its partnership with Red de Frios to manage energy usage in one of its 2,500 square foot frozen food warehouses at Almacén Ruíz Cortines in Monterrey, Mexico. Viking Cold’s patented TES system reduces overall electricity consumption and shifts energy usage to less expensive periods of the day. This project is the first of its kind in Mexico, the second largest economy in Latin America, and marks the first installation of Viking Cold Solutions’ technology in Latin America outside of the Caribbean.

Read More →

Viking Cold Solutions, Inc. and Dreisbach Enterprises were selected to be first presenters in a brand new webinar series hosted by the Global Cold Chain Alliance (GCCA) and brought to you by Tippman Innovation. Collin Coker of Viking Cold and Jason Dreisbach of Dreisbach Enterprises share how Thermal Energy Storage has helped Dreisbach’s California facility re-balance the scale between temperature stability and energy charges for low-temperature cold storage facilities. They talk through data-backed information on how thermal energy storage serves as a much-needed heat sink to balance energy and protect customers’ products. Jason further describes why his company chose to embrace this thermal energy solution, describes their experience with installation, and how the technology transformed their operation.

Viking Cold Solutions, Inc. and Dreisbach Enterprises were selected to be first presenters in a brand new webinar series hosted by the Global Cold Chain Alliance (GCCA) and brought to you by Tippman Innovation. Collin Coker of Viking Cold and Jason Dreisbach of Dreisbach Enterprises share how Thermal Energy Storage has helped Dreisbach’s California facility re-balance the scale between temperature stability and energy charges for low-temperature cold storage facilities. They talk through data-backed information on how thermal energy storage serves as a much-needed heat sink to balance energy and protect customers’ products. Jason further describes why his company chose to embrace this thermal energy solution, describes their experience with installation, and how the technology transformed their operation.