- All Posts

- All News

- Awards

- Blog Articles

- Case Studies

- Cold Storage

- Cold Storage Construction

- Energy Storage

- Food Processing

- News Articles

- Press Releases

- Solar + Storage

- Supermarket

- Utility & Grid

- Webinars & Podcasts

Viking Cold Solutions Wins AESP Energy Award

Viking Cold Solutions Wins AESP Energy Award

Left to right: Jen Szaro, James Bell, Rebecca Troutfetter Viking Cold Solutions is recognized by the Association of Energy Services Professionals’ (AESP) inaugural Innovations in Demand Flexibility award today at their annual conference in San Antonio, Texas. The award was received by James Bell, Viking Cold Solutions’ President and CEO, and presented by Jen Szaro, President & CEO of AESP, and Rebecca Troutfetter, Vice President of Engineering & Corporate Impact at CLEAResults. AESP, a leading industry trade group advancing the energy industry, introduced the Innovations in Demand Flexibility award this year. This competition for the award spanned various demand flexibility programs, such as renewable energy projects, distributed energy resource programs, demand response initiatives, microgrids, decarbonization efforts, and electrification programs. Viking Cold Solutions' Thermal Energy Storage (TES) technology consistently achieves positive impacts on business operations, the electricity grid, and the environment. Beyond its energy demand management and electrical efficiency achievements, TES helps address critical issues like food waste and food insecurity by better preserving food quality while also conserving electricity. Additionally, TES's unique ability to store and more efficiently utilize renewable energy assists with efforts to accelerate the decarbonization of the power grid, contributing to a more sustainable energy landscape. Viking Cold Solutions monitors all sites 24/7/365 to ensure clients’ peace of mind, and all parties can view performance metrics and historical data through the cloud-based portal. Some examples of demand flexibility and efficiency include the deployment of Viking Cold’s innovative energy technology in regional food banks from coast to coast which resulted in quantifiable and meaningful positive impacts. By reducing energy costs, TES technology provides hundreds of thousands of additional meals to Americans suffering from food insecurity. This further demonstrates Viking Cold's commitment to addressing energy and environmental challenges while creating a positive economic and social impact through practical local initiatives. Viking Cold Solutions builds lasting partnerships with our clients and stays engaged throughout the life of facilities with ongoing data collection, optimization initiatives, and utility incentive programs. Through these initiatives, TES technology has saved over 44 million kWh of electricity, avoided over 34 thousand tons of GHG emissions, and earned millions of dollars in incentives for our clients. For further details on the AESP Energy Awards, please visit AESP. To learn more about Viking Cold's technology and how it can reduce energy consumption to enhance the sustainability of cold storage facilities, reach out to Viking Cold today!

Frozen Food Month: The Path to Growing Sustainably

Frozen Food Month: The Path to Growing Sustainably

In recent years the popularity of frozen food has steadily increased in the United States. However, during the pandemic, frozen food experienced a surge in demand. The Food Institute reports that frozen food sales increased by 21%, with the pandemic serving as a major contributing factor to this growth. The pandemic-induced lockdowns and social distancing measures led to significant changes in people's eating habits, and many turned to frozen foods for their convenience, long shelf life, nutritional value, and ability to be stored in bulk. Source: Quartz Despite a steady increase in dollar sales, unit sales of frozen food fell in 2021 and 2022 by 3.2% and 5.1%, respectively, highlighting the potential impact of inflation on frozen food costs, reported the Food & Beverage Insider. Notwithstanding these declines, unit sales are still higher than they were before the pandemic, demonstrating that the demand for frozen foods remains strong – in part thanks to millennials who have now become frozen food’s largest consumers. According to the Food Navigator, older millennial shoppers, who are approaching the age of 40, represent 48% of the consumers of frozen foods. This generation prioritizes health and wellness and values a wider range of culinary options that use premium ingredients with fewer additives and preservatives. Alongside nutrition, they also demand convenience and sustainability in their food choices. With over 3,700 options in the frozen food section, there is something for every taste and lifestyle, notes the National Frozen & Refrigerated Foods Association. The growing popularity of frozen food has led 29% of consumers to expand their freezer space since the pandemic began, reported the American Frozen Food Institute. As demand for frozen food products increases, retailers are seeking ways to optimize their freezer sections while also reducing energy consumption for higher quality and more efficient frozen food storage. Companies like Viking Cold Solutions are helping retailers and distributors to not only improve the efficiency of their cold storage system by up to 50% but also increase facility resiliency. These advancements indicate a promising and sustainable future for frozen food. With all the demands on consumers’ lives, the greater convenience and quality of frozen foods meet a growing priority. The frozen food industry now has innovative new technologies to sustainably address consumers’ needs while reducing energy costs. Given the challenges of inflation and an unstable economy, it will be interesting to observe the further developments of frozen foods and cold storage technologies over the next few years. Learn more about Viking Cold’s sustainable Thermal Energy Storage technology here.

Houston Food Bank Will Feed More with Energy Savings

Houston Food Bank Will Feed More with Energy Savings

The Houston Food Bank distributes over 158 million meals every year to people struggling with hunger. With the help of more than 1,600 community partners to combat hunger and food insecurity, the Houston Food Bank provides individuals with food assistance as well as programs and services targeted at achieving long-term food stability. According to the Houston Food Bank, around 1 million people in southeast Texas are food insecure – 1 in 7 people face hunger as well as 1 in 5 children. Following the pandemic, food insecurity and unemployment increased dramatically. 53 million people sought assistance from food banks and neighborhood programs in 2021 to put food on their table. To help manage energy costs, the Houston Food Bank is partnering with Viking Cold Solutions and plans to install Thermal Energy Storage (TES) technology in their temperature-controlled facilities. TES systems are a cost-effective way to store and manage the large amounts of energy required by refrigeration equipment in cold storage facilities. Developed and patented by Viking Cold, the TES system will reduce electrical consumption and demand during peak energy usage hours inside the Houston Food Bank’s cold storage warehouse and will improve temperature stability inside their freezer. Cold storage facilities, such as frozen food warehouses, have the highest energy demand per cubic foot of any building. During peak energy use periods, they can account for up to 70 percent of the total electricity bill for organizations. The TES system's energy savings will enable the Houston Food Bank to offer thousands of additional meals every year and feed more people. Viking Cold’s partnership will help the Houston Food Bank better manage its energy usage by providing cutting-edge technology that will benefit the organization and support its mission for many years to come. Viking Cold Solutions has partnered with food programs across the United States as part of the Feeding America network, the nation’s largest domestic hunger-relief organization. For more information about Viking Cold Solutions’ Thermal Energy Storage systems, click here.

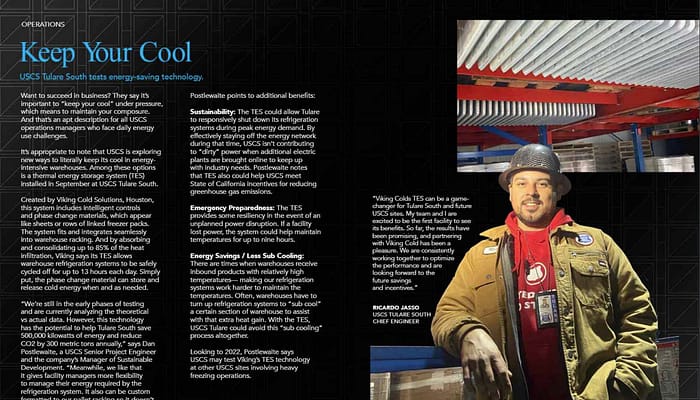

Case Study: USCS Safely Cuts GHG Emissions While Reducing Electrical Costs

Case Study: USCS Safely Cuts GHG Emissions While Reducing Electrical Costs

Situation: United States Cold Storage (USCS) is one of the top refrigerated warehousing and related logistics services companies operating throughout North America. Their Tulare South facility is a 116,482 square foot frozen food warehouse located in the agriculturally focused Inland Empire of Southern California. The state of California has committed to reaching a goal of 100% renewable and zero-carbon electricity by 2045, and USCS is just as committed to reducing their energy usage. To help California meet its energy demand reduction goals, USCS set out to focus on energy efficiency and better temperature control in their energy-intensive warehouses. Challenge: Operations managers at USCS face daily energy use challenges. To help alleviate these issues, USCS chose their Tulare South location to explore options with energy-saving technologies. The goals were to safely meet California's energy demand reduction initiatives by lowering demand and greenhouse gas (GHG) emissions while also addressing energy-use concerns, decreasing costs, and increasing sustainability and resiliency. Solution: USCS adopted Thermal Energy Storage (TES) technology to reduce their carbon footprint and lower their energy costs. Viking Cold Solutions installed energy meters, sensors, and controls throughout Tulare South’s temperature-controlled warehouse to monitor its operations and performance. Viking Cold then installed energy storage modules containing environmentally friendly Phase Change Material (PCM) which, when combined with cloud-based optimization algorithms, allowed Tulare South to control when and how it uses and procures energy. The facility's digitization, energy storage, and cloud-based optimization allows Viking Cold to continuously assess and improve the performance of USCS’s frozen food warehouse. Outcome: By utilizing Viking Cold's TES technology and optimization services, USCS lowered Tulare South’s peak period demand by more than 30% and refrigeration energy consumption by 25%, resulting in an annual carbon footprint reduction of over 350 tons at this facility. The frozen food warehouse not only increased energy efficiency but also increased temperature stability in the freezer by over 40%, better protecting the food. Operators of cold storage facilities, businesses with refrigeration loads, and utilities that need to control peak demands on the electrical grid all stand to gain significantly from Thermal Energy Storage. USCS Tulare South is a prime example of how TES technology effectively lowers energy demand and consumption while improving temperature stability in cold storage facilities. As a result, operational costs are reduced, product is protected, and environmental effects are minimized. For a more detailed account of Thermal Energy Storage and its benefits, download the USCS Tulare South Case Study.

Viking Cold Receives Top Tech Startup Award

Viking Cold Receives Top Tech Startup Award

Viking Cold Solutions has been awarded the first-ever Top Tech Startup Award by Food Logistics and Supply & Demand Chain Executive. This award recognizes top software and technology startups in the supply chain and logistics industry. According to Food Logistics and Supply & Demand Chain Executive, technology and software companies are leading the way in supply chain innovation. Many of today's tech startups are positioned to significantly disrupt the supply chain space with their innovations in artificial intelligence, robotics, fulfillment execution, and real-time visibility. “The future of the supply chain industry is directly impacted by the development of these new technologies, and I’m very excited to see what’s next for these winners,” says editor-in-chief of Food Logistics and Supply & Demand Chain Executive, Marina Mayer. Viking Cold Solutions is honored to be included amongst the industry's top disrupters. Our technology empowers solutions and services that significantly reduce GHG emissions, operational costs, and business risk for cold storage operations with high refrigeration-based energy loads. Our focus is to make cold storage systems more sustainable, efficient, and resilient for the world. To view the full list of Top Tech Startup Award winners, visit the Food Logistics and Supply & Demand Chain Executive websites. For more information on Viking Cold’s award-winning technology, and how it can reduce energy consumption and increase the sustainability of your cold storage facilities, contact us today!

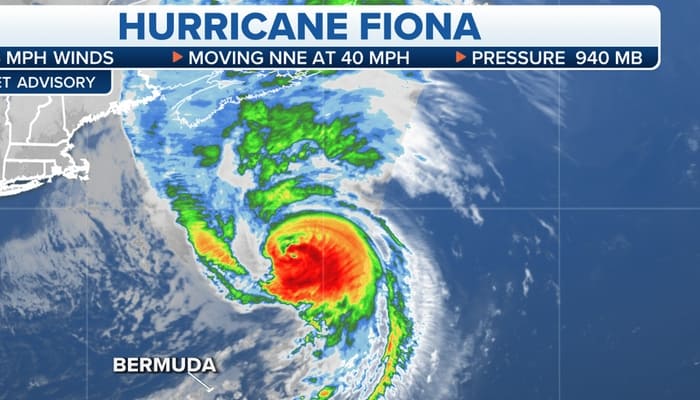

Isla Frio Partners with Viking Cold for Hurricane Resiliency

Isla Frio Partners with Viking Cold for Hurricane Resiliency

Isla Frio’s cold storage facility, in Cidra on the island of Puerto Rico, was well prepared with a back-up generator and fully charged Thermal Energy Storage (TES) when Hurricane Fiona made landfall on Sunday, September 18th. The island was overwhelmed by historic amounts of rainfall, ranging from 6 to 20 inches, with some areas receiving over 3 feet of rain from the storm. As the days progressed, Hurricane Fiona strengthened and left the entire island without power. Fortunately, the resilient combination of TES and back up generation allowed Isla Frio to maintain their required safe temperatures throughout the storm – and for days longer than other facilities – by running the generator only during the day and turning it off at night to save diesel. In fact, diesel consumption was reduced by over 50% and extended the time the generator could run from 6 days to over 12 days. Chart 1 – Isla Frio’s Main Freezer Temperature from September 5 - 23 Source: Viking Cold Solutions’ Cold Chain PortalTM In Chart 1, the change to the temperature settings to a -10 Fahrenheit setpoint before the hurricane is clear on September the 10th. This provided fully charged Thermal Energy Storage to work intermittently with Isla Frio’s generator and allowed Isla Frio to maintain safe temperatures throughout the hurricane without products ever passing -5 degrees Fahrenheit – even without any power. Isla Frio kept their clients’ products safe and were immediately able to help feed the people of Puerto Rico during their time of need. As a trusted partner to dozens of Puerto Rico’s food storage and distribution businesses, Viking Cold Solutions was there before Hurricane Fiona, during the storm, and now to help the island recover by providing resilient, safe, and energy efficient temperature control technology. Chart 2 – Isla Frio’s Cooler & Freezer Temperatures from September 18 - 23 Source: Viking Cold Solutions’ Cold Chain PortalTM Isla Frio’s TES system maintained facility temperatures day after day, as pictured in Chart 2, even when there was no power available by providing supplemental refrigeration and intelligent control. The TES technology reduced temperature stratification and cut temperature fluctuations while absorbing and consolidating 50% to 85% of heat infiltration. Our 24/7 remote monitoring and notification service kept our clients at Isla Frio well informed about their facility during the storm and provided valuable data for effective decision making. As Hurricane Fiona churns its way past Bermuda, Viking Cold Solutions was already there working with our clients to again weather the storm. We’re relieved that our Puerto Rico clients are recovering quickly with our resilient technology and look forward to helping more businesses get through extreme weather and manage expensive, intermittent electricity. Whether it’s a hurricane, equipment failure, forest fires, or other natural or man-made disasters, Viking Cold Solutions’ resilient sustainability technology is there to help. For more information about how our TES technology can help your facility, click here.

Today Is World Energy Storage Day!

Today Is World Energy Storage Day!

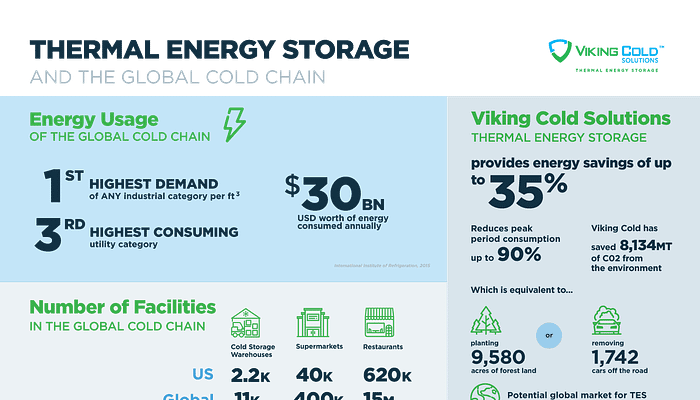

Energy storage is a rapidly evolving technology and has been advancing to the forefront of the electrical industry, shifting the focus to the effective integration of renewable energy. Various international enterprises recognized the increasing value of energy storage and have created World Energy Storage Day to commemorate its significance. This global movement is celebrated on September 22nd every year by policy officials, associations, and industries working to promote and adopt energy storage, e-mobility, and green technology for a more sustainable future. According to the Energy Storage Association, energy storage is an enabling technology; it saves consumers money, improves reliability and resilience, integrates generation sources, and helps reduce environmental impacts. It’s a key element for the entire grid, augmenting resources from wind, solar, and hydropower as well as nuclear and fossil fuels, demand-side resources, and system efficiency assets. By tapping into energy storage during outages, businesses can continue normal operations and avoid costly disruptions. When demand shifts and baseload resources can’t react quickly enough, energy storage can inject or extract energy to match the load as needed, making the grid more responsive and reducing the need to build backup power plants. The effectiveness of energy storage is based on its ability to respond quickly to changes in demand, the rate at which energy is lost during the storage process, the total amount of energy it can store, and the speed at which it can be recharged. More than 90% of global grid battery storage is dominated by lithium-ion batteries, which are today's most widely used battery storage alternative, reports the Environmental and Energy Study Institute. However, there are multiple types of energy storage that can provide large-storage capacities, such as pumped hydro, compressed air, and thermal. With the rapid development of energy storage, business owners and policymakers are looking towards more environmentally friendly sources of energy storage beyond lithium-ion batteries. According to Precedence Research, the global energy storage systems market size is projected to surpass $435 billion by 2030 and grow at a CAGR of over 8% from 2022 to 2030. Record investments in energy storage are being fueled by declining costs and new incentives. As reported by the Environmental Defense Fund, costs for energy storage have declined by 74% since 2013 and are projected to decline 8% per year through the mid 2020s. In fact, the cost of some storage has decreased so quickly that many utilities are switching to renewable energy combined with storage instead of investing in expensive new natural gas power plants. Over the next ten years, combining energy storage with renewable energy sources could completely change the way we purchase, sell, and utilize energy. State and Federal laws, such as the Inflation Reduction Act of 2022, are also opening new market opportunities and revenue streams, which will be the primary driver of growth outside of cost. Incentives can bridge market gaps and assist in further market adoption. In the U.S., certain industries such as cold storage, consume over $50 billion in energy annually. Refrigeration energy cost is one of the top operating expenses which drives demand from operators for energy reduction technologies. These businesses include over 4,200 cold storage warehouses, more than 40,000 grocery store freezers, and over 620,000 restaurant freezers. To help these businesses, Viking Cold Solutions developed and commercialized thermal energy storage technologies that offer both sustainability benefits and deliver proven 20% to 35% energy savings in temperature-controlled environments. With the growing concern over the prices of fossil fuels, their environmental impacts, and the capacity and resilience of energy grids around the world, stakeholders are increasingly turning their attention to energy storage solutions. To learn about how thermal energy storage technology reduces energy use and carbon emissions while increasing resiliency, click here.

New Law Promotes Transformative Changes in Clean Energy

New Law Promotes Transformative Changes in Clean Energy

The clean energy landscape dramatically shifted due to the signing of the Inflation Reduction Act of 2022 on August 16th. This new law significantly increases the tax incentives available for energy transition initiatives and technology while removing many of the roadblocks that have hindered the United States’ shift to cleaner energy. Certain industries will see a major rise in financing due to these new regulations, which will alter how capital is managed and invested, tax credits are monetized, and clean energy projects are financed. $369 billion will be spent on climate and clean energy initiatives, including tax subsidies for electric and renewable vehicles, investments in U.S. production of sustainable technologies, and environmental justice. The Act also authorizes the Department of Energy to issue guarantees of up to $250 billion for clean energy projects. Norton Rose Fulbright notes that these fall under three types of energy infrastructure projects. One type is projects that retool, repower, reuse, or replace outdated energy infrastructure. Another is attempting to make energy infrastructure operational so that air pollution or greenhouse gas emissions can be avoided, reduced, used, or sequestered. The third type of projects consist of initiatives to repair environmental harm brought on by energy infrastructure. The Act is also extending the project eligibility to dedicated energy storage and geothermal energy. According to J.P. Morgan, solar and wind production have been down the last few years in part due to the uncertainty surrounding the renewable Investment Tax Credits (ITCs) and Production Tax Credits. However, with the Inflation Reduction Act, we can expect to see an increase in wind and solar production. Additionally, there will be a new standalone 30% investment tax credit for energy storage, particularly battery, pumped hydro, and thermal. Wood Mackenzie predicts that a 30% storage Investment Tax Credit would lead to a 20-25% rise in U.S. storage deployments over the next five years. Many analogies have been made to the solar business, where, according to the Solar Energy Industries Association, the Investment Tax Credit was one of the most important government policy tools for fostering industry growth. The solar industry has expanded by more than 10,000% since the ITCs implementation in 2006. The Inflation Reduction Act further offers long-term tax credit incentives for a wide range of renewable energy technologies. These incentives represent a considerable improvement over the current energy tax credit programs, which were only applicable to a restricted number of technologies and have been the subject of continuous phase-out and extension cycles during the past two decades. With the guarantee of a long-term and steady tax credit through at least the next ten years, the majority of clean energy technologies, such as wind, solar, biomass, thermal, and carbon capture, are now more financially viable. A variety of innovative energy transition technologies that had not previously qualified for tax credits are now eligible for subsidies under the Act, including energy storage projects, clean energy manufacturing facilities, hydrogen projects that adhere to minimum carbon emission standards, biogas production facilities, and current nuclear power plants. With new incentives for energy storage, companies such as ours can more cost effectively deploy energy saving technologies to more clients and industries. The Inflation Reduction Act will open many doors for energy storage and those interested in temperature control and thermal energy management. With our Thermal Energy Storage, Viking Cold has developed the only proven, environmentally friendly way to store renewable energy in the refrigerated and temperature-control industries. We look forward to using the provisions of the Inflation Reduction Act to help businesses to be more efficient and reduce their carbon footprint while lowering their energy costs up to 50%. Whatever its other impacts, the Inflation Reduction Act of 2022 is the broadest ranging legislation to address sustainability and decarbonization of the energy sector in our lifetime. To read the Inflation Reduction Act in full, click here. For more information on how thermal energy storage can help manage refrigeration energy costs, click here.

How Viking Cold Can Help Your Energy Efficiency Goals

How Viking Cold Can Help Your Energy Efficiency Goals

Energy costs around the U.S. have been climbing leaving consumers wondering "how high will they go?" States such as Hawaii, Massachusetts, and California have the highest electricity rates in the country, with California as the second-largest energy consumer in the nation after Texas. In the last five years, electricity costs in the Los Angeles area exceeded the national average by 34% or more since 2018 – see Chart 1. Chart 1: Average prices for electricity U.S. & Los Angeles Source: U.S. Bureau of Labor Statistics Despite California’s high-energy consumption, its per capita energy consumption is less than most states due in part to its mild climate and its energy efficiency programs. The Golden State primarily produces electricity from solar, geothermal, and biomass energy, making it one of the most energy-efficient states in the country – but that isn’t enough for California. The state has committed to reaching a goal of 100% renewable and zero-carbon electricity by 2045, and the California Energy Commission (CEC) is leading the way. The CEC supports energy research and development programs to spur innovation in energy efficiency and has lately completed a major study on the route to zero net energy (ZNE), which includes Viking Cold Solutions’ Thermal Energy Storage (TES) in the blueprint for a path to net zero emissions for commercial buildings. The Viking Cold TES system was installed in the walk-in grocery freezer at a San Francisco Whole Foods store. This installation included Phase Change Materials (PCM) mounted on the ceiling of the walk-in freezer as well as cloud-based intelligent controls integrated with the existing refrigeration controls. According to the report, refrigeration accounts for a majority of the store’s electrical load, therefore thermal PCM, also known as thermal energy storage or TES, is a promising method for storing small amounts of excess energy. TES allows refrigeration compressors to run less often when energy costs are high (and energy production is low) and to run more often and store thermal energy when energy costs are low (and there is excess generation). This reduces cycling of the compressors and refrigeration energy costs, ultimately improving the efficiency of existing refrigeration systems. This is done by increasing the percentage of the total refrigeration run time that occurs during hours with lower ambient temperatures, thereby running the compressors at higher efficiency levels – see Chart 2. Chart 2: Plot comparing the predicted baseline energy with post-retrofit energy consumption for Viking Cold System Source: CEC Report, Figure D-9 TES technology combines intelligence with PCM to maximize the energy efficiency of the refrigeration system. Viking Cold PCM cells add thermal mass to a room, providing the ability to hold designated temperatures for much longer periods, which helps reduce refrigeration runtimes. Intelligent controls and an energy-management system help maintain a constant temperature and alert operators about any mechanical malfunction or power outage. The CEC study concluded that TES technology produced 25% energy savings and was proven as an applicable energy conservation measure to help achieve California’s energy efficiency goals. The results of this study were released by the CEC as a blueprint for a successful path to ZNE commercial buildings in California, but this blueprint could easily be one for the entire world. Read more about Viking Cold’s approach to cold storage efficiency here. For additional information about the CEC study, click here.

Viking Cold Solutions Wins pv magazine’s Sustainability Award

Viking Cold Solutions Wins pv magazine’s Sustainability Award

pv magazine recently recognized Viking Cold Solutions as the 2021 Sustainability Award winner for its innovative Thermal Energy Storage (TES) technology and services. This accolade is awarded to companies with technological innovations and groundbreaking solutions in the solar and energy storage industries. An independent panel of jurors cited the energy efficiency and the scalability of the company’s TES technology as two of the reasons Viking Cold was selected over hundreds of other companies vying for awards. This international recognition of TES technology's contributions to greater efficiency and reduction of greenhouse gas emissions from energy-intensive temperature-controlled facilities supports Viking Cold’s core mission: To transform refrigeration by reducing its carbon footprint, operating costs, food loss, and electrical grid impacts using innovative Thermal Energy Storage technology and services. The Sustainability Award was presented to Viking Cold during a globally live-streamed ceremony from Berlin, Germany, in February. View full video: here. During the event, pv magazine’s panel discussion with Viking Cold’s CEO, James Bell, further revealed that TES technology offers an effective and sustainable solution to a major environmental challenge: food degradation and waste. In fact, Viking Cold has developed the only proven, environmentally-friendly way to store solar energy in the cold storage industry. James commented, “TES allows energy-intensive refrigeration equipment in C&I facilities to be cycled down during peak hours of the day, effectively cutting the production of carbon emissions and reducing carbon footprint by tens of thousands of metric tons.” Users can expect improved temperature stability and to save up to 50% on their energy expenses while improving their refrigeration system efficiency by 20% to 30%. With a 20-year system life and no mechanical components, TES is an effective solution to managing demand and storing solar or other renewable energy in the cold chain. “This is an ingenious and very efficient solution to solar’s ‘duck curve’ problem and we hope to see widespread deployment,” said one juror from the selection committee. Read more about Viking Cold's approach to cold storage efficiency here. For more details on our recent awards and milestones, check out our latest press release. And for more information about a TES solution for your facility, contact us here.

Another successful TES installation for a sustainability focused 3PL company

Another successful TES installation for a sustainability focused 3PL company

Initial results show 20%-30% energy savings on a recent deployment of Thermal Energy Storage technology in a US Cold facility in Tulare, California. US Cold references the energy saving and carbon reducing technology in their quarterly newsletter- the Shield- accessible here. Here at Viking Cold we are excited that another world class company has embraced the energy and cost savings of TES technology and the sustainability and carbon reduction that it provides to the cold chain which consumes more electricity than any other source except lighting. #sustainability #carbonreduction #vikingcoldsolutions

Another Successful, Sustainable Thermal Energy Storage Installation in Mexico

Another Successful, Sustainable Thermal Energy Storage Installation in Mexico

Viking Cold has successfully installed another Thermal Energy Storage (TES) and refrigeration optimization system inside a third-party logistics frozen food warehouse in Mexico. Our client, Frigoríficos ARCOSA, is a leading cold storage provider with distribution centers across Mexico and has over three decades of experience providing temperature-controlled solutions and support services to their food & beverage and retail clients. They are also proud members of the Global Cold Chain Alliance (GCCA). Operating energy-intensive refrigerated facilities in Mexico presents many challenges. Not only do operators like ARCOSA have to deal with the expected business and logistical challenges of cold storage, but the energy market in Mexico has variability which creates difficulties for operations budgets and profitability. After payroll, energy related expenses are typically the second highest cost for cold storage facilities, and refrigeration can be up to 90% of their energy costs. Without technologies and strategies that add energy flexibility, variable energy prices can negatively impact the bottom line. In Mexico, like many other places around the globe, energy prices vary based on time-of-use with consumption and demand charges significantly higher during peak periods and intermediate peak periods (sometimes referred to as partial peak periods). Because cold storage warehouses must maintain temperatures to protect food quality, technologies that safely reduce refrigeration energy consumption and demand during Mexico’s high-priced periods without loss of temperature control are critical to cold storage profitability. With these needs in mind, ARCOSA approached Viking Cold to see if refrigeration optimization and TES technology with Phase Change Material (PCM) could provide the energy flexibility needed to reduce energy costs and GHG emissions in their refrigerated warehouses in Mexico. Viking Cold first evaluated their 64,000 square foot freezer in Juquila. At the time of evaluation and installation, this plant experienced intermediate peak prices up to 17 hours per day and peak prices up to four hours per day with some seasonal variations. The operating strategy had three goals: Minimize energy demand (kW) and reduce energy consumption (kWh) during each of the seasonal peak periods and intermediate periods Maintain temperature protocols Not increase energy use during any period An interface between existing refrigeration controls and Viking Cold’s refrigeration optimization software was implemented, additional sensors were added, and TES modules containing PCM specifically engineered to the warehouse’s temperature requirements were easily integrated into the existing warehouse infrastructure. Results have exceeded expectations, since installation of the TES and refrigeration optimization solutions: Demand reductions over 380 kW during all peak periods Annual weather-normalized consumption reduction of over 400,000 kWh - the equivalent of 280 metric tons of GHG emissions Temperatures held within requirements Approximately $120,000 (MEX$2,400,000) of annual savings at current energy prices ARCOSA owner and President Gabriel Guzman noted, “ARCOSA’s partnership with Viking Cold has begun with positive results for both cost reductions and sustainability improvements that we hope to replicate in our other facilities.” The flexibility Viking Cold provided to manage when and how their refrigeration system uses electricity has provided ARCOSA with confidence that when energy market changes do occur, they have technology-enabled flexibility that reduces energy risks and improves the sustainability of their cold chain operations.

North American Clean Energy: Why Refrigerated Warehouses Need Long-Duration Thermal Energy Storage

North American Clean Energy: Why Refrigerated Warehouses Need Long-Duration Thermal Energy Storage

North American Clean Energy has published an article by Viking Cold's Director of Marketing, Damon Vance, that discusses how many commercial & industrial (C&I) refrigerated warehouses across the country are contributing to solutions for some of the challenges on the electrical grid. The C&I facilities in the cold chain, when utilizing energy storage and refrigeration optimization solutions like Viking Cold's, represent a significant opportunity to help reach the goals of utility operators and the Biden Administration's $36 billion decarbonization plan. By enabling cold chain facilities with added sustainability, resiliency, and flexibility operators of both cold storage and the electrical grid can reduce costs and GHG emissions. Read the article or contact Viking Cold to learn more about the intense electrical load, aging infrastructure, and rapid growth rate of the refrigerated cold chain and how new technologies like Thermal Energy Storage (TES) are helping them improve refrigeration efficiencies, reduce their carbon footprint, and contribute to the growth of renewable energy sources as we enter the energy transition.

Inbound Logistics Podcast: Sustainable and Profitable Refrigerated Logistics

Inbound Logistics Podcast: Sustainable and Profitable Refrigerated Logistics

Jeof Vita, the host of the Inbound Logistics Podcast, spoke with Viking Cold President & CEO, James Bell to discuss how Thermal Energy Storage (TES) technology is helping cold chain operators balance their need to be more sustainable and profitable with the amount of refrigeration required to protect their food's quality (Episode 118). Utilizing Viking Cold's refrigeration optimization solutions to address the unique temperature and energy challenges of different cold storage facilities from food producers and 3PL providers to foodservice distributors and retailers is also discussed. Additionally, they cover how the unique energy storage and efficiency capabilities of TES are improving how refrigerated facilities are interacting with the electrical grid for improved sustainability and reduced operating costs.

Refrigeration Engineers Presentation – Efficient, Flexible, Sustainable Refrigeration with Thermal Energy Storage

Refrigeration Engineers Presentation – Efficient, Flexible, Sustainable Refrigeration with Thermal Energy Storage

Refrigeration engineers often receive a lot of valuable training and education through their professional organizations. Viking Cold's Global Director Brad North, P.E., CEM presents some of the key benefits of Thermal Energy Storage (TES) using Phase Change Material (PCM) in refrigeration applications to a national HVAC and refrigeration engineering association. In this 21-minute video presentation to engineers in the HVACR industry, refrigeration benefits such as reducing energy use, improving sustainability, minimizing temperature stratification, extending temperature resiliency, and improving interconnectivity with power from the electrical grid are covered. Brad begins his presentation with relevant cold chain statistics about facilities where refrigeration optimization with intelligent Thermal Energy Storage is being achieved by leveraging PCM. He also explains some of the unique thermodynamic properties of PCM that allow TES systems to achieve positive refrigeration energy and temperature management results. He then covers how the PCM is configured and easily installed into various cold storage refrigerated facilities without additional space requirements or the loss of valuable storage area. Also covered in the presentation is a brief evolutionary history of the refrigeration practice known as flywheeling – subcooling the food and surrounding room to then minimize refrigeration during periods with high energy costs. Brad discusses factors that influenced the start of flywheeling, are transforming flywheeling practices with new technologies, as well as how PCM safely extends the length of flywheeling periods while reducing the risk to food quality and shelf life. He also shares how PCM is able to slow temperature increases in a room without active refrigeration and shows case study data illustrating a reduced rate-of-rise and improved temperature stability. Inside cold storage facilities temperature stratification throughout the room generally occurs. Brad shows some examples of how properly installed PCM combined with intelligence reduces the extent of temperature stratification and creates a more uniform temperature across the vertical space of these refrigerated rooms. With the introduction of PCM a new “stratification floor” is created that consolidates more of the heat near the ceiling in the airflow of the evaporators for improved temperatures around the food and for easy removal of the heat by the refrigeration system. Thermal Energy Storage is often considered a way to simply shift when energy is consumed by refrigeration systems. Brad explains many of the factors that allow Viking Cold’s TES technology to not only shift the timing of refrigeration but also to safely reduce the total kWh energy consumption (energy efficiency) of the refrigeration systems. Hear about the factors that enable this such as reducing the horsepower per ton ratio, the ability to run refrigeration systems at maximum designed efficiency or “fully loaded”, the consolidation of up to 85% of the heat infiltration near the top of the room, the PCM’s higher heat capacity and heat transfer rates, and the fact that TES systems do not have mechanical components that cannibalize the energy savings with parasitic losses. Also discussed in this refrigeration engineer's presentation are additional attributes of TES that provide energy flexibility and the ability to safely and easily participate in multiple utility and grid operator programs. Many of these programs reduce costs, some provide financial incentives for technology upgrades, and some programs can generate revenue streams for operators of refrigerated facilities. The added refrigeration flexibility from TES enables participation in programs such as demand response, permanent load shed, targeted load shed, peak shaving, responding to market index pricing signals, renewables plus storage, and capacity programs. Temperature resiliency inside the refrigerated cold chain is paramount to maintaining food quality and shelf life while minimizing food loss. Brad also explains how PCM adds resiliency to cold storage rooms. Common scenarios that disrupt cold storage operations and create a need for temperature resiliency are becoming more common and include mechanical breakdown of refrigeration system components and loss of power from ice storms, hurricanes, wildfires, utility-initiated de-energization, and more. Refrigerated facilities that have TES installed have up to three times longer temperature protection during any of these situations that may cause the loss of refrigeration. Whether you are a facilities or business leader, refrigeration engineer, cold storage operator, or somewhere in the temperature-controlled cold chain, there is something in this short professional association presentation for you. Quickly learn about mitigating risk, cutting costs, improving sustainability, stabilizing temperatures, and more. Click above to watch this short 21-minute refrigeration engineer professional association presentation. Or contact us today to learn how our refrigeration optimization and thermal energy storage solutions will save you energy and money.

Viking Cold Earns 5th Top Green Provider Award from Food Logistics

Viking Cold Earns 5th Top Green Provider Award from Food Logistics

Viking Cold Solutions Named Top Green Provider by Food Logistics for Fifth Consecutive Year The award recognizes companies whose products, services or exemplary leadership are enhancing sustainability within the cold food and beverage industry HOUSTON, June 22, 2021 - Viking Cold Solutions, the leading thermal energy storage and refrigeration optimization service provider for low-temperature cold storage industries, announces it has been included in the 2021 Top Green Providers list from Food Logistics for the fifth consecutive year, underscoring the company's sustainability contributions to the global cold chain. The editorial staff evaluates a company’s participation in such programs as the EPA’s SmartWay and other recognized sustainability programs; facilities that are LEED-certified and/or feature solar panels, LED lighting and other energy-saving installations and retrofits; and other means of producing measurable reductions in GHG emissions. "When the pandemic hit, I thought for sure that sustainability would be pushed to the wayside. But, in fact, the complete opposite happened. And, I couldn’t be more appreciative of the supply chain industry’s efforts in making sustainability top of mind in every aspect of their organization despite the many supply chain disruptions they continue to face,” said Marina Mayer, Editor-in-Chief of Food Logistics and Supply & Demand Chain Executive. “Sustainability is the key to success, and the recipients of this year’s award prove that when sustainability matters to them, they will continue to do great things and make a difference in the industry.” Viking Cold Solutions Director of Marketing Damon Vance shared: "We are honored to once again be recognized by Food Logistics as a Top Green Provider. Our goal is not only to deliver cost-effective optimization solutions to refrigerated facilities but to also offer sustainable technology that helps preserve our planet for future generations." Recipients of this year’s award will be profiled in the June 2021 print issue. Go to www.FoodLogistics.com to view the full list of all 2021 Top Green Providers. About Viking Cold Solutions Viking Cold Solutions is the leading long-duration thermal energy storage and refrigeration optimization service provider to the energy-intensive frozen/low-temperature cold storage industry. Viking Cold delivers cost-effective and flexible energy management services which protect food and help reduce the environmental impact of refrigeration. Its patented Thermal Energy Storage system with phase change material (PCM) and intelligent controls reduce cold storage energy costs up to 35 percent or more, while improving temperature stability and optimizing refrigeration operations. Viking Cold Solutions’ TES systems have been measured, verified, and incentivized by energy utilities across the U.S. and are currently in use around the world providing efficiency to grocery stores, low-temperature warehouses, and restaurants. For additional information, please visit www.vikingcold.com. About Food Logistics Food Logistics is the only publication exclusively dedicated to covering the movement of product through the global cold food supply chain, focusing on trucking, warehousing, packaging, risk management, food safety and more. Go to www.FoodLogistics.com. Press Contact: Damon Vance Marketing Director dvance@vikingcold.com +1.832.899.4771

Energy Cast Podcast: Thermal Thinking with Viking Cold

Energy Cast Podcast: Thermal Thinking with Viking Cold

Jay Dauenhauer, the host of Energy Cast podcast, recently interviewed James Bell, Viking Cold President & CEO. They discuss predecessors in the thermal energy storage (TES) market, lessons learned, the benefits of Viking Cold's TES solutions, and why TES is critical to the future electrical grid and the entire food distribution network. Listen to this fast-paced interview to hear more about how TES is shifting refrigeration load (the highest on the grid per cubic foot), reducing refrigeration consumption (third highest behind only lighting and HVAC), cutting costs for our clients in the food industry, a few nuggets about the genesis of Viking Cold, and the "lightning round" conversation about the future of energy technologies.

Dairy Foods: Mechanization picks ups steam in dairy processing warehouses

Dairy Foods: Mechanization picks ups steam in dairy processing warehouses

A recent article in Dairy Foods Magazine highlights the mechanization and automation trends in dairy food production facilities. Topics include materials-handling automation, software upgrades, refrigeration optimization, automated storage and retrieval systems (AS/RS), and how technologies will be integrated to maximize efficiency, traceability, transparency, storage density, optimal material flow, and to better manage warehouse labor in their operations. Viking Cold's VP of Sales & Marketing, Collin Coker, was interviewed along with other food production warehouse technology providers including LIDD, Tippman Group, Signode Industrial Group, Applied Net Solutions, Westfalia Technologies Inc., and Quest Industrial LLC.

Grocery Business Q&A: How Grocers Are Getting Smarter About Cold Storage

Grocery Business Q&A: How Grocers Are Getting Smarter About Cold Storage

Winsight Grocery Busines editor, Christine LaFave Grace, discussed how grocery retailers are getting smarter about their cold storage assets with Viking Cold President & CEO, James Bell. Effects from the pandemic, digitalization, new technology advancements, and more are discussed. How is consumer behavior driving new store layouts and needs for additional refrigerated spaces that require temperature and energy optimization? How has sustainability been reprioritized since the start of the pandemic?

POWER: Distributed Generation Part of Puerto Rico Rebuild

POWER: Distributed Generation Part of Puerto Rico Rebuild

POWER Magazine's Associate Editor Darrell Proctor recently published an article focused on the rebuilding of Puerto Rico's electrical grid after a number of devastating hurricanes including Hurricane Maria in 2017. "The Puerto Rico Electric Power Authority has embarked on a $20 billion plan to rebuild the island’s power grid. The initiative includes a commitment to generate 40% of the island’s power from renewable resources by 2025, and 100% by 2050. C&I enterprises using distributed power generation are a large part of the effort." The article highlights Viking Cold as one of the leading sustainable Distributed Energy Resources (DER) delivering cost-effective, reliable, and resilient power to the island's industrial and commercial businesses. Isla Frio, a cold storage company on the island, is building a new 147,000 square foot facility with Viking Cold's Thermal Energy Storage (TES) technology to add hurricane-resistant food storage capacity to the island. The second phase of the project will include the addition of onsite solar power generation. The combination of renewables with the existing TES installed during construction will maximize the cost-effectiveness of their solar-plus-storage investment and help Puerto Rico meet its aggressive goals to add resilient renewable generation to the grid.

New Warehouse Podcast: Digitization & Sustainability in Refrigerated Warehouses

New Warehouse Podcast: Digitization & Sustainability in Refrigerated Warehouses

Kevin Lawton, the host of The New Warehouse Podcast, interviewed Viking Cold Solutions' President & CEO James Bell to discuss the current and future state of digitization and sustainability inside refrigerated warehouses. They discuss how digitization and thermal energy storage work in cold storage to maximize the efficiency, resiliency, and sustainability of the cold chain. The conversation also covers some of the additional levels of complexity of refrigerated spaces and how the impacts of the pandemic have driven the adoption of technologies such as WMS, automation, robotics, and thermal energy storage inside refrigerated warehouses. James and Kevin also discuss the market conditions driving more construction of cold storage facilities and how digitization and new technology is being included in the design and building of new warehouses. Additionally, Kevin and James cover the electrical grid impacts of refrigerated spaces, and how with thermal energy storage and warehouse digitization operators can reduce costs and create new revenue streams. Listen to the full conversation on the podcast here: EP 150: Digitization and Sustainability in Refrigerated Warehouses with Viking Cold Solutions

Viking Cold Collects 2020 FL100+ Award

Viking Cold Collects 2020 FL100+ Award

Food Logistics has recognized Viking Cold Solutions among the top logistics software providers for 2020, as one of the leading software and technology partners to the food and beverage industry, for the second year in a row. The publication named Viking Cold as a winner of its 2020 FL100+ Award in recognition of the significant reductions in both energy usage and costs and operational improvements that Viking Cold’s Thermal Energy Storage (TES) technology delivers in cold chain settings. Now in its 17th year, the FL100+ is a highly respected annual listing of top logistics software providers that are addressing the unique challenges of today’s food and beverage supply chain. Recipients are judged to deliver products and services that support efficient transportation and warehousing, minimize operational waste, facilitate safe operations, and assure regulatory compliance. Viking Cold was selected for the strengths of its innovative Thermal Energy Storage (TES) technology, which equips cold chain facilities with the means to enhance refrigeration efficiency and increase operational resilience. This not only helps customers reduce their carbon footprint, but also achieves a reduction in energy costs of up to 50%. Combining environmentally friendly phase change materials with a powerful suite of cloud-based operational tools, TES integrates easily with existing controls to provide real-time monitoring and analytics of temperatures, equipment status, and energy use. These data-driven insights are made available to warehouse managers via the Viking Cold client portal with custom reports, notifications, and analytics giving them the actionable intelligence to improve cold storage operations and reduce costly peak-period energy consumption for up to 13 hours per day. All the while, TES ensures stable refrigerated temperatures are maintained, which safeguards food products, limits waste, and minimizes disruption during periods of downtime or power outage. The full list of FL100+ Award winners was revealed by Food Logistics in an announcement on December 16. Full details will be published in the November/December 2020 print issue of the magazine. For more information on the technology behind Viking Cold’s award-winning thermal energy storage solution, and how it can reduce energy consumption and costs for your food warehousing operations, get in touch today.

Viking Cold Wins Green Supply Chain Award 2020

Viking Cold Wins Green Supply Chain Award 2020

Viking Cold is delighted to have been named a winner at the Green Supply Chain Awards 2020 in recognition of its commitment to help customers reduce their carbon footprint. The win is a testament to the strengths of Viking Cold’s highly efficient Thermal Energy Storage (TES) technology, which optimizes refrigeration, lowers demand and overall power consumption in high-demand cold storage applications, and delivers benefits to both the environment and the bottom line. The Green Supply Chain Awards, co-ordinated by Supply & Demand Chain Executive magazine, celebrate companies working to achieve sustainability goals as well as providers of supply chain solutions and services that support customers in their carbon-reduction efforts. Winners were selected for their ability to demonstrate a clear sustainable supply chain strategy and provide evidence of how they are executing on those strategies to deliver measurable results. Viking Cold’s TES technology, which has previously been recognized in the Green Supply Chain Awards, increases refrigeration system efficiency in cold storage environments by an average of 26%. It is based on the use of 100% recyclable thermal energy storage cells that contain environmentally friendly Phase Change Materials. Energy is stored in the cells for later release, enabling refrigeration equipment to be safely cycled off over long periods, limiting the amount of power being drawn from the grid while maintaining a consistent temperature to safeguard food quality. Viking Cold’s offering also incorporates a cloud-based suite of operational tools to deliver the data insight needed to optimize operations and energy usage and provide evidence of the savings generated. For more information on the Green Supply Chain Awards, visit the SDCE website. Contact us today to discuss how Viking Cold’s award-winning Thermal Energy Storage technology can help reduce energy consumption and enhance the sustainability credentials of your cold storage facilities.

Frozen Food Market Trends 2020

Frozen Food Market Trends 2020

The coronavirus pandemic has greatly disrupted the U.S. food industry, resulting in significant changes in consumer behavior and an increased demand for industrial cold storage warehouse space. With quarantines still in effect around most of the country, consumers have been forced to eat at home more and either “panic-buy” large quantities of extra groceries and/or shift to more online orders more frequently. Additionally, because of its longer shelf-life and surge in available options, the frozen food category has seen significant growth in both online and in-person grocery purchases, forcing grocery and cold storage facilities to scramble to keep up. According to the American Frozen Food Institute (AFFI), seven in 10 frozen food shoppers have increased the amount of frozen food they’re buying since the start of the pandemic. Six months in, U.S. shoppers are continuing to stock up their freezers with frozen meals, meats, ice cream, and frozen novelties. Not only is the number of consumers purchasing frozen food growing, but many have also switched to ordering directly online from restaurants and foodservice distributors. The question is: How has this rapidly changing behavior affected the cold storage industry – an essential element of our supply chain dedicated to protecting, delivering, and handling temperature-controlled goods in the United States. Warehouse demand, in general, has been accelerating in recent years, largely due to the booming e-commerce industry. The world’s largest commercial real estate services and investment firm, Coldwell Banker Richard Ellis (CBRE), examined the relationship between e-commerce grocery growth and cold storage warehouse capacity in its 2019 “Food on Demand Series: Cold Storage Logistics Unpacked” report, forecasting that in order to meet the demand generated by online grocery sales, an additional 75 to 100 million sq. ft. of industrial freezer and cooler space will be needed within the next five years – an increase of roughly 47%. CBRE researchers also suggest that much of the cold-storage sector’s growth is likely to occur in gateway markets like Los Angeles and the New York area, as well as in top food-producing states such as California, Texas, Wisconsin, Florida, and Washington state. As the pandemic persists, cold storage facilities are at record high capacity and struggling to keep up with the continuous demand. Cold storage facilities typically fall into the categories of public refrigerated warehouses (PRWs), foodservice and wholesale, grocery distribution centers and retail stores, and food processing facilities. Due to changing demand, PRWs have been forced to provide smaller, more frequent orders. National food industry news source, The Food Institute, stated that “Instead of supplying a full pallet of a single product to a warehouse, PRWs are now delivering a pallet with multiple products directly to the store. These small orders increase labor requirements and change transportation options drastically.” Many expect major PRWs to accelerate the industry’s consolidation trend in order to gain more control over the United States’ cold storage footprint. It is also expected that to address the changing market, cold storage facility operators will be proactively upgrading their warehouses with new technologies to improve operational efficiency and flexibility. Warehouse upgrades that are seeing a surge in popularity include technologies such as Viking Cold Solutions thermal energy storage (TES), warehouse management systems (WMS), and material handling automation and robotic systems. The intelligence platform of Viking Cold’s TES system not only optimizes temperatures and energy use, but provides valuable, actionable data that allows operators to make operational improvements. Additionally, there has been a growing interest in sustainable, carbon-reducing technologies. Viking Cold’s thermal energy storage systems also address these needs by increasing refrigeration energy efficiency an average of 26% while better protecting food and improving temperature resiliency. By absorbing and consolidating up to 85% of the heat infiltration, TES also allows refrigeration systems to be safely cycled off for up to 13 hours each day to avoid demand or time-of-use energy fees, while maintaining stable temperatures. The technology leverages existing refrigeration systems and easily integrates with controls, other data platforms, and racking structures to bring efficiency, flexibility, and additional food protection to the frozen food chain. The COVID-19 pandemic has accelerated changes in consumer behavior, implementation of technology, and broad market trends in the food industry. The entire distribution chain from food processors to logistics companies to retailers is under added pressure to make improvements to stay profitable and keep food on our tables. The future remains unclear but enabling technologies like Viking Cold’s TES are helping the food and beverage industry feed our families by improving operations, cutting costs, and lowering the GHG emissions of refrigeration.

Cold Facts: Cutting-Edge Warehouse Energy Alternatives

Cold Facts: Cutting-Edge Warehouse Energy Alternatives

Cold Facts magazine has listed Viking Cold Solutions among the cutting-edge warehouse energy technologies delivering cost-efficient and sustainable benefits in temperature-controlled applications. The magazine, published by the Global Cold Chain Alliance, included Viking Cold in an overview of technologies that have advanced in recent years to provide “savvy facilities” with new ways of answering their refrigeration challenges. The article explains how Viking Cold’s thermal energy storage (TES) technology allows operators to safely shift energy use during high-tariff periods to maximize cost savings while also reducing total energy consumption. It highlights how TES opens the door to more renewable energy use while enabling operators to take advantage of utility programs, incentives, and demand-response economics. James Bell, President & CEO of Viking Cold, noted that the cloud-based intelligence platform used to manage TES provides operators with the controls and visibility to maximize operational efficiency in cold storage facilities. At the same time, it minimizes the use of refrigeration equipment. He explained how it draws on real-time data to automate temperature optimization and energy consumption. The long-duration storage technology discharges for up to 13 hours per day to maintain stable temperatures that protect food quality and shelf life, even if electricity or equipment fails. Bell added that TES technology can interface with warehouse management systems, automation platforms, data analytics, and artificial intelligence (AI) tools. Adoption of all of these potentially powerful technologies is accelerating in the face of the COVID-19 pandemic, said Bell, as facilities look to closely measure, monitor, and limit energy consumption with a view to introducing greater cost reduction and enhancing sustainability. “Cold storage and electrical grid operators both are facing new energy challenges. As the world moves towards renewables and green sources of electricity, TES technology is a unique and powerful tool to help address these challenges,” Bell concluded. To read the full article on warehouse energy alternatives, visit the Cold Facts magazine page on the GCCA website. The article starts on page 28. For more information on Viking Cold’s cutting-edge thermal energy storage technology, and how it can enhance cost efficiencies and sustainability for your cold storage facilities, get in touch today.

Viking Cold Adds Voice to ESA Webinar

Viking Cold Adds Voice to ESA Webinar

Viking Cold provided insight into the advantages of its Thermal Energy Storage technology as part of an educational webinar hosted by the Energy Storage Association (ESA). The session, titled Thermal Energy Storage: Challenges and Opportunities, gave ESA members a chance to learn about the technologies and trends shaping the thermal energy storage sector, forming part of the association’s work to help establish a more resilient, efficient, sustainable, and affordable electrical grid. Marc Chupka, ESA’s Vice President of Research and Programs, welcomed Collin Coker, Vice President Sales & Marketing, to share an overview of Viking Cold’s Thermal Energy Storage technology and highlight how it fits into this landscape. Coker explained how TES has a drastically lower levelized cost of energy (LCOE) of two cents per kilowatt-hour (kWh), making it far more cost-effective than conventional electrical storage mediums, such as lithium-ion batteries. He briefed the ESA audience on the phase change materials (PCM) at the heart of Viking Cold technology, describing how it demonstrates significantly higher heat-absorption rates compared with frozen food, while continuously releasing cold energy to provide stable temperatures that protect products held in commercial & industrial (C&I) warehouse environments as well as grocery store and restaurant walk-in freezers. Coker pointed to the fact that resiliency is built into the Viking Cold TES solution since no power is required and the PCM can hold temperatures three times longer than the thermal mass of food alone, helping defend chilled environments against power outages, natural disasters, and mechanical failures. With intelligent controls to manage energy release over extended periods and 24/7 visibility of energy, temperature, and operational data, Coker added that Viking Cold brings greater levels of efficiency to cold chain environments while enhancing sustainability efforts. In the case of one customer, net power consumption has declined by 43% over a 13-hour period along with a 29% peak demand reduction, he said. Coker went on to highlight successful utility-supported programs involving Viking Cold’s TES technology, which includes a multi-customer project involving some of the largest food distribution companies in the world. In total, this initiative accomplished 1.3 megawatts (MW) of energy curtailment over a four hour ICAP period. He concluded with the findings from a third-party measurement and verification study, showing how one site is using Viking Cold’s TES technology in combination with excess solar power generation during the day to achieve a 95% reduction in overnight energy consumption, effectively taking the site off the grid. The ESA webinar is available in full, including access to the accompanying slides, via the ESA’s YouTube channel. For more information on how Viking Cold’s Thermal Energy Storage is bringing greater levels of resiliency, efficiency, sustainability, and affordability to cold chain environments, get in touch with us today.

POWER Magazine: Managing Demand with TES

POWER Magazine: Managing Demand with TES

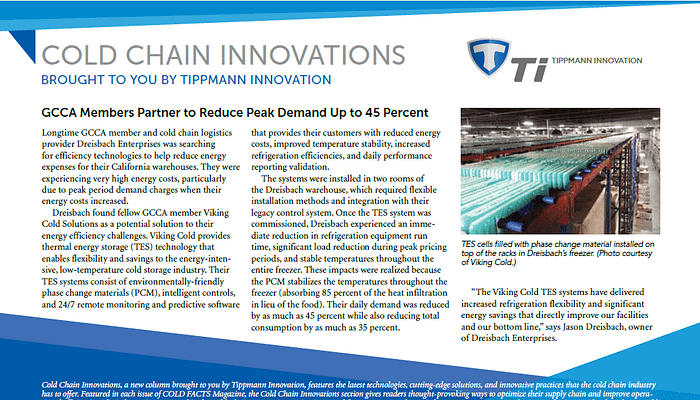

POWER magazine, a leading source of information for the power generation industry, has published an article highlighting the benefits of Viking Cold’s Thermal Energy Storage (TES) technology in managing power demand for utilities and cold storage customers. The article, authored by Collin Coker, Vice President of Sales and Marketing at Viking Cold, gave an overview of the changing energy landscape, where factors such as the increase in Distributed Energy Resources (DERs) and the variability of renewable generation sources are having a bearing on power providers’ ability to manage demand when and where it is needed. Coker points out that time of use, capacity, transmission, and distribution all impact the total cost of electricity for the end-user. This presents an acute issue for food businesses with commercial and industrial (C&I) refrigerated facilities, where a continuous energy supply is needed to control temperature fluctuations and avoid any damage being caused to the products being stored. Underlining this point, he cites data showing that C&I refrigeration sites have the highest demand per square foot of any industrial load, with energy often accounting for up to 70% of their total electric bill. Coker explains how Viking Cold’s TES technology has been designed specifically for such applications, using proprietary Phase Change Material that remains near a constant temperature while storing large amounts of energy that can be released over long periods, covering higher cost periods of peak demand. Among the Viking Cold clients the article highlighted as managing demand through the use of TES was Dreisbach Enterprises in Richmond, California, which has reduced demand between 300 kW to 500 kW for 13 hours per day, six days a week while also improving temperature stability by 50% and avoiding the technique of ‘flywheeling’ on the food. Overall, Dreisbach Enterprises was able to achieve a cut in freezer energy consumption of 35%. To read the full article, and for more news and insight into energy operations and maintenance, visit the POWER magazine website. For more information on how Thermal Energy Storage can bring greater control and cost-savings to your cold storage facility, get in touch with Viking Cold today.

Release: Xcel Energy’s Custom Thermal Storage Incentive Program

Release: Xcel Energy’s Custom Thermal Storage Incentive Program

VIKING COLD SOLUTIONS ANNOUNCES LAUNCH OF XCEL ENERGY'S CUSTOM THERMAL STORAGE INCENTIVE PROGRAM Utility Program Funds Up to 90% of Energy-Saving Technology Upgrades for Frozen Food Producers and Cold Storage Warehouse Operators in Colorado and Minnesota HOUSTON, Sept. 22, 2020 (GLOBE NEWSWIRE) -- Viking Cold Solutions, the leading thermal energy storage technology provider for the low-temperature cold storage and frozen food industries, announces the inclusion of its award-winning energy storage technology in Xcel Energy’s new Custom Thermal Storage Incentive Program, part of their Custom Efficiency programs in Colorado and Minnesota. As an industry leader in delivering clean energy solutions, Xcel Energy is currently offering significant funding for energy-saving technology upgrades, such as Viking Cold’s Thermal Energy Storage (TES) systems, which safely reduce demand and add temperature resiliency and efficiency to low-temperature facilities with large energy needs. The majority of the TES system and installation costs will be funded by Xcel Energy’s Custom Thermal Storage Incentive Program and the remainder can be paid for out of the energy savings. By working with the utility to deploy innovative technology that addresses grid challenges and reduces emissions, owners of cold storage and frozen food facilities can save up to 25% or more on their monthly energy costs. “Xcel Energy’s support of Viking Cold technology is further confirmation that TES creates value for both the utility as well as frozen food and cold storage customers. The utilities are incentivizing customers to upgrade their facilities with the latest efficiency and sustainability technology, such as TES, to provide safe, long-duration demand reduction. This helps customers in Colorado and Minnesota achieve their financial and sustainability goals,” said Collin Coker, Viking Cold’s Vice President of Sales & Marketing. Viking Cold works directly with Xcel Energy representatives to assist customers through the program application process to maximize incentives, install the TES technology, and optimize the facility’s operation and energy use. To learn more about how to save money while reducing your environmental impact and to initiate the application process, go to vikingcold.com/xcel. In addition to Xcel Energy, Viking Cold Solutions is proud to collaborate on demand management and efficiency programs in partnership with other prominent U.S. utilities shaping a clean energy future, including Eversource Energy, National Grid, Pacific Gas & Electric Co., Southern California Edison Co., San Diego Gas & Electric Co., and many more. ### About Xcel Energy Xcel Energy provides the energy that powers millions of homes and businesses across eight Western and Midwestern states. Headquartered in Minneapolis, the company is an industry leader in responsibly reducing carbon emissions and producing and delivering clean energy solutions from a variety of renewable sources at competitive prices. For more information, visit xcelenergy.com. About Viking Cold Solutions Viking Cold Solutions is the leading long-duration thermal energy storage technology provider to the energy-intensive frozen/low-temperature cold storage and frozen food industries. Viking Cold delivers cost-effective and flexible energy management services that protect food and help reduce environmental impact. Its patented Thermal Energy Storage system with phase change material (PCM) and intelligent controls reduces cold storage energy costs up to 25 percent or more, while sustainably improving temperature stability and optimizing refrigeration operations. Viking Cold Solutions’ TES systems have been measured, verified, and incentivized by energy utilities across the U.S. and are currently in use around the world providing energy management and efficiency to utilities, grocery stores, low-temperature warehouses, and restaurants. Viking Cold Colorado Contact: Adam Valmoro Regional Director avalmoro@vikingcold.com +1 949.375.3551 (m) Viking Cold Minnesota Contact: Brad North Regional Director bnorth@vikingcold.com +1 302.383.0138 (m) Press Contact: Damon Vance Marketing Director dvance@vikingcold.com +1 832.899.4771

New Cold Storage Construction with TES in Puerto Rico

New Cold Storage Construction with TES in Puerto Rico

Cold storage firm, Isla Frio Refrigeration Corp., recently acquired a former PepsiCo bottling and distribution plant in Cidra, Puerto Rico. The 147,000 square-foot building on eight acres is being fully renovated to become a state-of-the-art frozen and refrigerated food warehouse, beginning with 50,000 square feet of frozen storage. The end goal of the $10 million project is to supply hurricane-resistant cold and dry storage space for the island while also providing thermal resilience with our Thermal Energy Storage (TES) technology for temperature-controlled goods in the event of a power outage. Over the years, Puerto Rico has been hit exceptionally hard by natural disasters and other crises, and with an unreliable power grid, these events inflict significant impacts on supply chain efficiency and functionality. During Hurricane Maria in 2017 and the lengthy power loss that followed, our clients’ facilities on the island did not lose any food product, thanks to the TES systems they have installed. The recent coronavirus pandemic has also amplified the growing need for more cold storage capacity and the island-wide shortage of warehouse space. The recent acquisition of the PepsiCo plant provides an opportunity to build a highly efficient, energy-secure cold storage facility to support the recovering supply chain and electrical grid on the island. The energy resources of this construction project are in alignment with the guiding principles of Puerto Rico’s overall grid modernization plan. Led by the Puerto Rico Electric Power Authority (PREPA), the $20 billion plan will reconstruct the island’s grid, ultimately dividing it into eight self-sufficient mini-grids and providing residents with a safer, greener, and more resilient energy supply. In addition, the island has committed to generating 40% of its power from renewables by 2025 and 100% by 2050. These ambitious clean energy goals will drive the widespread adoption of renewable energy generation, which is complemented through the use of sustainable energy storage technologies like our TES systems. “Puerto Rico has always been very important to Viking Cold Solutions. Our first warehouse installation was on this beautiful island, and it’s appropriate that our first new cold storage construction project be right here in Cidre, PR,” said Paul Robbins, Founder of Viking Cold Solutions. The Isla Frio project, which began construction in June 2020, will be Viking Cold’s first system installation to be part of a facility’s original design and construction plan; previous installations have been facility retrofit projects. Phase One will be to install our technology and get the cold storage facility up and running by December. Phase Two will build out the rest of the site and may eventually include an onsite solar power resource to assist in powering the facility. Once the plant is operational with TES technology, carbon emissions and energy use will be minimized, enhanced energy resilience and flexibility will be in place, and the facility will benefit from lower electricity costs – a significant value on an island with among the highest electricity costs in the U.S. The building itself is connected to a large diesel generator to provide backup power and is built at a high elevation, better protecting it from floods. During extended grid interruptions or power outages, the generator and its fuel can be conserved because the TES technology provides built-in temperature resilience to protect food up to several days without power. We are proud to again be working with another Puerto Rico-based company, this time to help them build their cold storage resources in a sustainable way right from the start. By implementing our energy storage technology, Puerto Rico is one step closer to meeting its goal of generating 100% of its power from renewables by 2050.

Impact Investment and Viking Cold Solutions

Impact Investment and Viking Cold Solutions